High Quality Long Lasting Ceramic Bead Media-Ceramic Beads B80 180-250 microns

High Quality Long Lasting Ceramic Bead Media-Ceramic Beads B40, 250-425 microns

The main component of zirconia ceramic sand is zirconium oxide, which is mainly used for surface treatment such as sandblasting and shot peening.

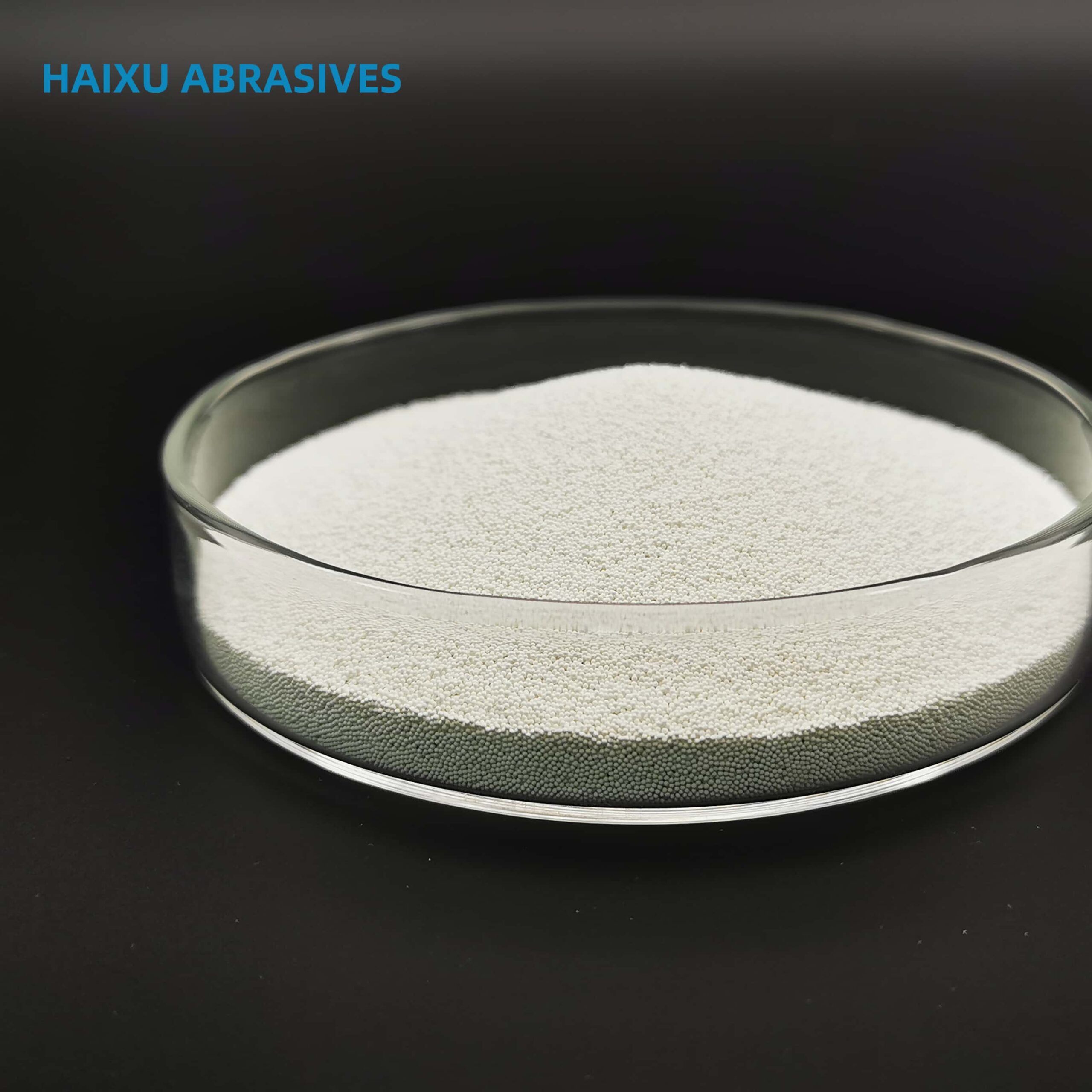

The production process of ceramic sand is to melt high-quality imported zircon sand into liquid at high temperature, and then blow it into balls.

The manufactured zirconia ceramic spheres are screened and magnetically separated to remove impurities to obtain high roundness, high strength and uniform particle size particles.

The spherical particles of ceramic sand can achieve better surface brightness during the sandblasting process, and the workpiece itself does not change color.

It is widely used in sandblasting and surface treatment in industries such as aviation parts, stainless steel plates, structural parts, stainless steel kitchenware, medical devices, mobile

phone/laptop housings, automobile chassis/engines, sports equipment, etc.

PHYSICAL PROPERTIES

| Specific Weight | 4.30g/cm3 |

| Mohs Hardness | 7.0 |

| Vickers/Rockwell hardness | 700HV/60HRC |

| Bulk density | 125um and above: 2.30g/cm3, 125um and below: 2.1-2.2g/cm3 |

TYPICAL CHEMICAL ANALISIS [%]

| Component | Typical value (%) | Conventional value (%) |

| ZrO2 | 63.80 | 60-70 |

| SiO2 | 26.82 | 28-33 |

| AL2O3 | 9.08 | Max 10 |

| Fe2O3 | 0.03 | Max 0.1 |

| TiO2 | 0.24 | Max 0.4% |

Model Specifications

| Model | Particle size range |

| B20 | 600-850 um |

| B30 | 425-600 um |

| B40 | 250-425 um |

| B60 | 125-250 um |

| B80 | 180-250 um |

| B100 | 125-180 um |

| B120 | 63-125 um |

| B125 | 0-125 um |

| B170 | 45-90 um |

| B205 | 0-63 um |

| B400 | 30-63 um |

| B500 | 10-30 um |

Mainly Applications

Medical: Surface treatment such as burr removal on stainless steel surgical instruments and titanium alloy human implants.

High-speed rail: It can be used for sandblasting the surface of high-speed rail aluminum alloy parts to enhance the metal texture and form a smooth satin effect. It is used for grinding and finishing high-speed rail rails.

Automobile: Ceramic sand can be used to clean the surface of automobile engine castings and remove burrs; it can be used to clean the welds and welding points of automobile floor to prepare for subsequent spraying; it can be used for shot peening strengthening of automobile springs to improve fatigue life. It can be used for beautification sandblasting of aluminum alloy automobile wheels to eliminate stress and improve impact resistance.

Mold and machining: It can be used for sandblasting of stainless steel molds, copper molds, aluminum alloy molds such as tire molds, injection molds, and stamping molds to improve surface finish. Clean the flash and burrs of machined parts.

Electronic equipment: Ceramic sand is used for sandblasting the shells of mobile phones, tablets, and watches made of aluminum alloy or stainless steel. The surface roughness and glossiness can be adjusted as needed, and it has anti-fingerprint properties.

Kitchenware industry: used for sandblasting of fine stainless steel cookware, pot bottoms, soup spoons and other products, giving the products a delicate metal texture and a certain antibacterial ability.

Glass products industry: used for atomization treatment of glass, replacing the hydrofluoric acid chemical etching process to prevent pollution.

Aviation parts shot peening: used to improve the fatigue resistance of aviation mechanical parts such as carbon steel, titanium alloy, aluminum alloy, etc., and eliminate surface stress. Specifically, it can be used for surface strengthening of aircraft wings, aircraft engine turbine blades, turbine disks, gears, and landing gear.

PACKAGING

25 kg bags or drums

SCHX_Admin –

looks like a good product