Garnet sand 90/120mesh 100# for Process Glass in Waterjets

Introduction

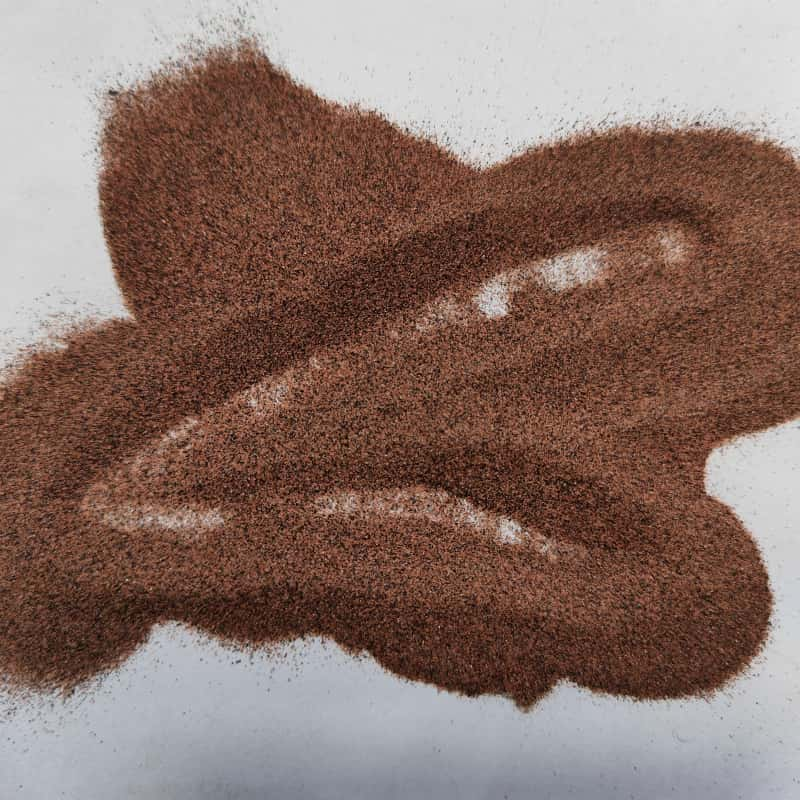

Garnet sand is a highly efficient and naturally occurring abrasive material widely used in waterjet cutting applications, particularly for processing glass. The 90/120 mesh 100# garnet sand is specifically engineered to deliver superior cutting performance, precision, and cost-effectiveness. Its uniform grain size, high hardness, and exceptional durability make it an ideal choice for waterjet operators seeking clean, smooth cuts in glass materials.

Why Choose Garnet Sand for Waterjet Cutting?

Garnet is a preferred abrasive in waterjet cutting due to its unique properties:

High Hardness (7.5-8.5 on Mohs Scale): Ensures efficient material removal without excessive wear on equipment.

Angular Grain Structure: Enhances cutting speed and precision.

Chemical Inertness: Prevents contamination and reactions with the workpiece.

Low Dust Generation: Improves workplace safety and reduces clogging in waterjet systems.

Recyclability: Can be reused in certain applications, reducing operational costs.

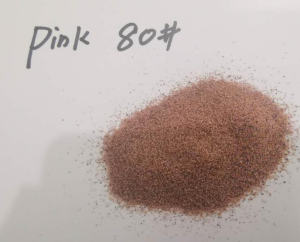

90/120 Mesh 100# Garnet Sand – Optimal for Glass Processing

The 90/120 mesh (100#) garnet sand is specially graded for waterjet cutting of glass, offering:

1. Superior Cutting Performance

The medium-coarse grain size balances cutting speed and edge quality, preventing chipping or cracking in glass.

Ensures smooth, burr-free finishes with minimal kerf width.

2. Consistent Particle Size Distribution

Tightly controlled mesh size (90/120) minimizes nozzle wear and maximizes abrasive flow efficiency.

Reduces clogging and ensures stable cutting performance.

3. High Purity & Low Silica Content

Meets industrial safety standards (OSHA/NIOSH) with <1% free silica, reducing health risks.

Non-toxic and environmentally friendly compared to synthetic abrasives.

4. Cost-Effective & Long-Lasting

Harder than other abrasives like aluminum oxide, leading to longer usable life.

Lower consumption rates reduce overall operational costs.

Applications in Glass Processing

This garnet abrasive is ideal for:

Precision cutting of tempered glass, laminated glass, and mirrors.

Intricate designs in decorative and architectural glass.

Automotive and electronic glass components.

Conclusion

For waterjet cutting of glass, 90/120 mesh 100# garnet sand provides the perfect balance of speed, precision, and economy. Its superior hardness, consistent grain size, and eco-friendly properties make it the top choice for manufacturers seeking high-quality finishes and extended nozzle life.

SCHX_Admin –

looks like a good product

Thomasicern –

https://soundcloud.com/roscarpt

KennethGuelt –

https://gravatar.com/dependable3fd17c19e0

avenue17 –

And I have faced it. We can communicate on this theme.

Scottsmoge –

https://pastelink.net/dmxygm3c

Albertosen –

виртуальный номер тайланда

Albertosen –

south africa virtual number https://virtual-local-numbers.com/countries/42-southafrica.html

Jamesreest –

аренда катера

PeterAtore –

yacht rental tenerife https://european-sailing.com/yacht-charter-tenerife

RonaldEnurb –

https://everevo.com/event/92300

Albertosen –

kroatien yachtcharter https://eurosegeln.com/yachtcharter-kroatien