The Critical Role of Garnet Abrasive in Waterjet Cutting

July 3, 2025 – In the world of industrial cutting technologies, garnet abrasive has emerged as the gold standard for waterjet systems, delivering unmatched precision and cost efficiency. As manufacturers increasingly adopt abrasive waterjet cutting (AWJ) for hard materials, garnet’s unique properties make it the preferred choice across aerospace, automotive, and glass industries.

Why Garnet? The Science Behind Superior Performance

Garnet, a naturally occurring mineral with a hardness of 7.5-8.5 on the Mohs scale, offers three key advantages in waterjet cutting:

Optimal Cutting Efficiency

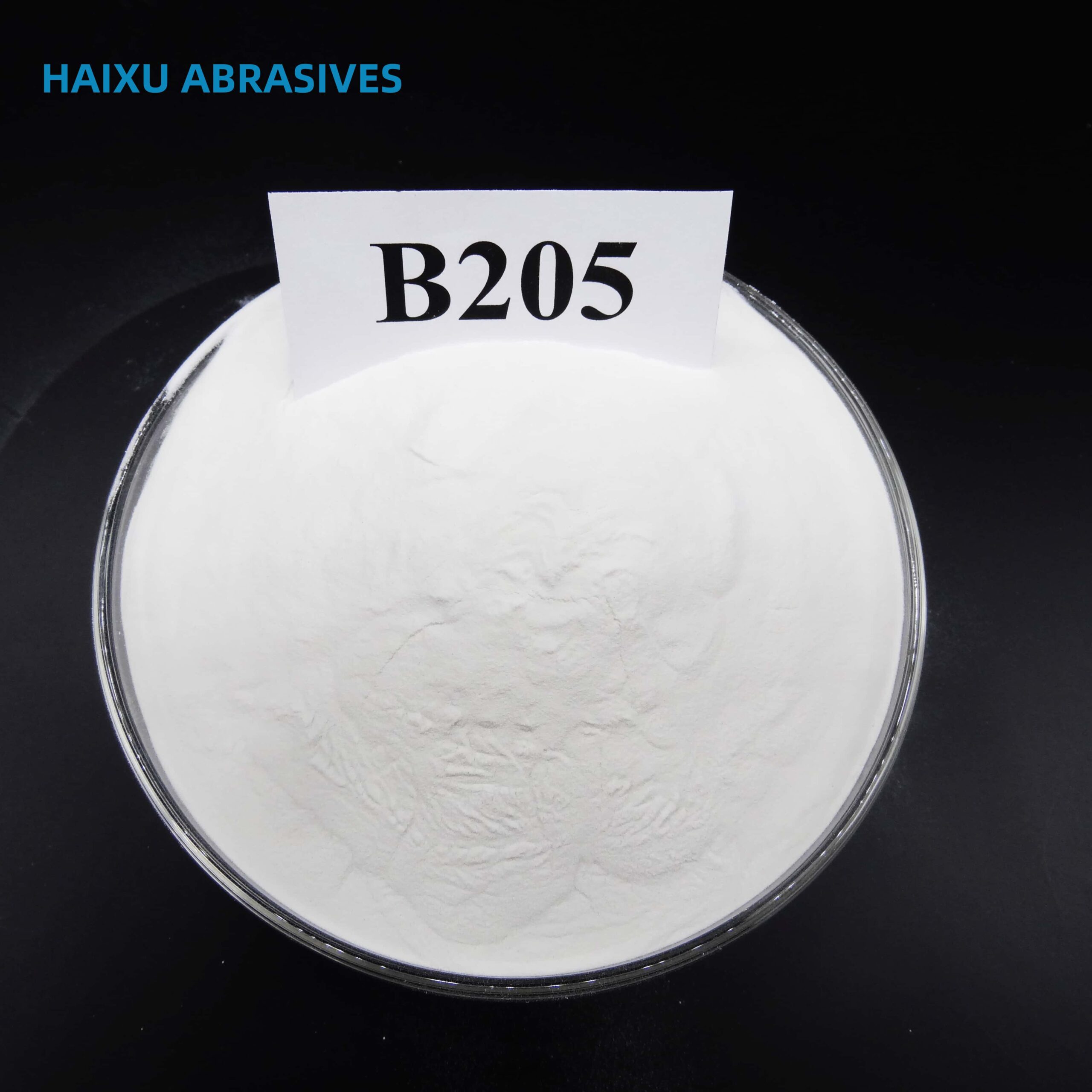

Its angular grain structure creates micro-impact fractures in materials, enabling cleaner cuts than rounded abrasives.

The 80#-120# mesh size (most common in AWJ) provides the ideal balance between cutting speed and surface finish.

Economic and Environmental Benefits

Garnet lasts 20-30% longer than synthetic alternatives like aluminum oxide, reducing abrasive consumption by up to 40%.

Low silica content (<1%) makes it OSHA-compliant, while its recyclability lowers waste disposal costs.

Material Versatility

Proven effective on hardened steel (up to 200mm thick), titanium alloys, laminated glass, and carbon fiber composites.

Generates minimal heat, preventing warping in sensitive aerospace components.

Industry Applications

Aerospace: Used to cut turbine blades and CFRP components with tolerances of ±0.1mm.

Automotive: Envents burr-free cutting of EV battery trays and aluminum chassis parts.

Architectural Glass: Delivers polished edges on tempered glass without micro-cracks.

Market Trends and Innovations

With the global waterjet market projected to reach $1.5 billion by 2026 (CAGR 6.2%), garnet suppliers are developing:

High-density garnet (SG >4.2) for faster cutting of Inconel.

AI-driven abrasive recovery systems that reuse garnet up to 3 times.

“Garnet remains irreplaceable in AWJ because it combines geological durability with engineered consistency,” says Dr. Elena Torres, materials scientist at MIT. “New coating technologies may further enhance its lifespan by 15% within two years.”

As industries demand greener manufacturing, garnet’s natural origin and recyclability position it as the sustainable abrasive solution for tomorrow’s waterjet challenges.