Application of aluminum hydroxide flame retardant in PVC and PP

PVC

Polyvinyl chloride (PVC) is a cheap polymer material and easy to process. However, when it burns, it produces a large amount of smoke, decomposes toxic and corrosive gases, and is suffocating. It is the main cause of death in fires. Applying aluminum hydroxide to PVC effectively overcomes the above shortcomings.

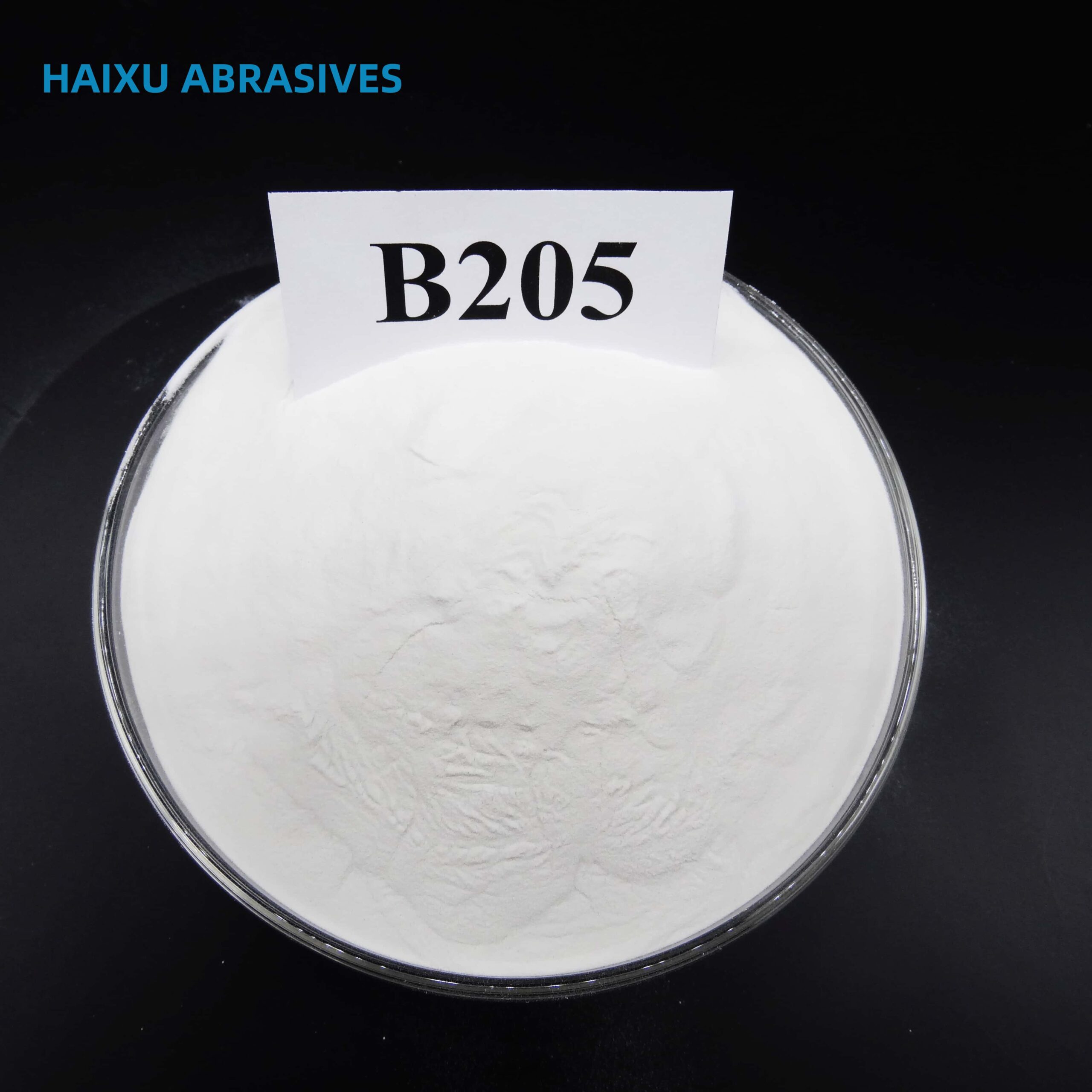

Aluminum hydroxide surface-treated with coupling agent can also significantly reduce the smoke density of plastics, and has little impact on the mechanical properties of the material. Within the dosage range of 20 to 30 parts, it is an excellent flame retardant and smoke suppressant. , has broad application prospects.

PP

(1) Aluminum hydroxide has obvious flame retardant and smoke elimination effects in polypropylene (PP). As the dosage of aluminum hydroxide increases, its oxygen index rises linearly, while the burning speed and smoke amount decrease significantly.

(2) The smaller the particle size of aluminum hydroxide, the better the flame retardancy and the smaller the adverse effect on mechanical properties.

(3) Surface treatment of aluminum hydroxide with an effective activator is an indispensable part of the application of aluminum hydroxide in polypropylene. The effect of activated aluminum hydroxide on the flame retardancy and mechanical properties of PP is significantly less than that of unactivated aluminum hydroxide.

(4) Aluminum hydroxide can be used together with phosphorus and halogen flame retardants to improve flame retardant properties.