Properties

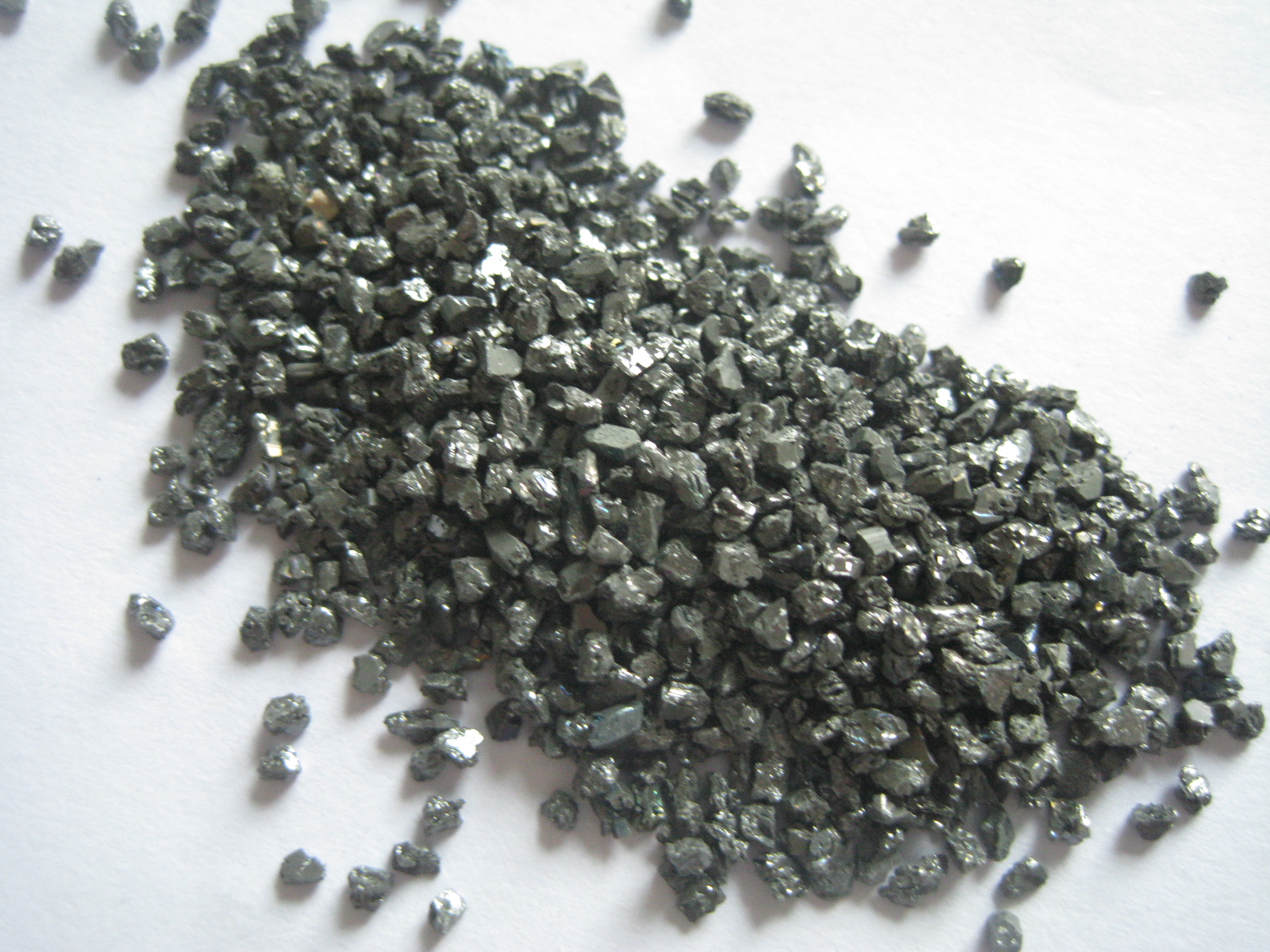

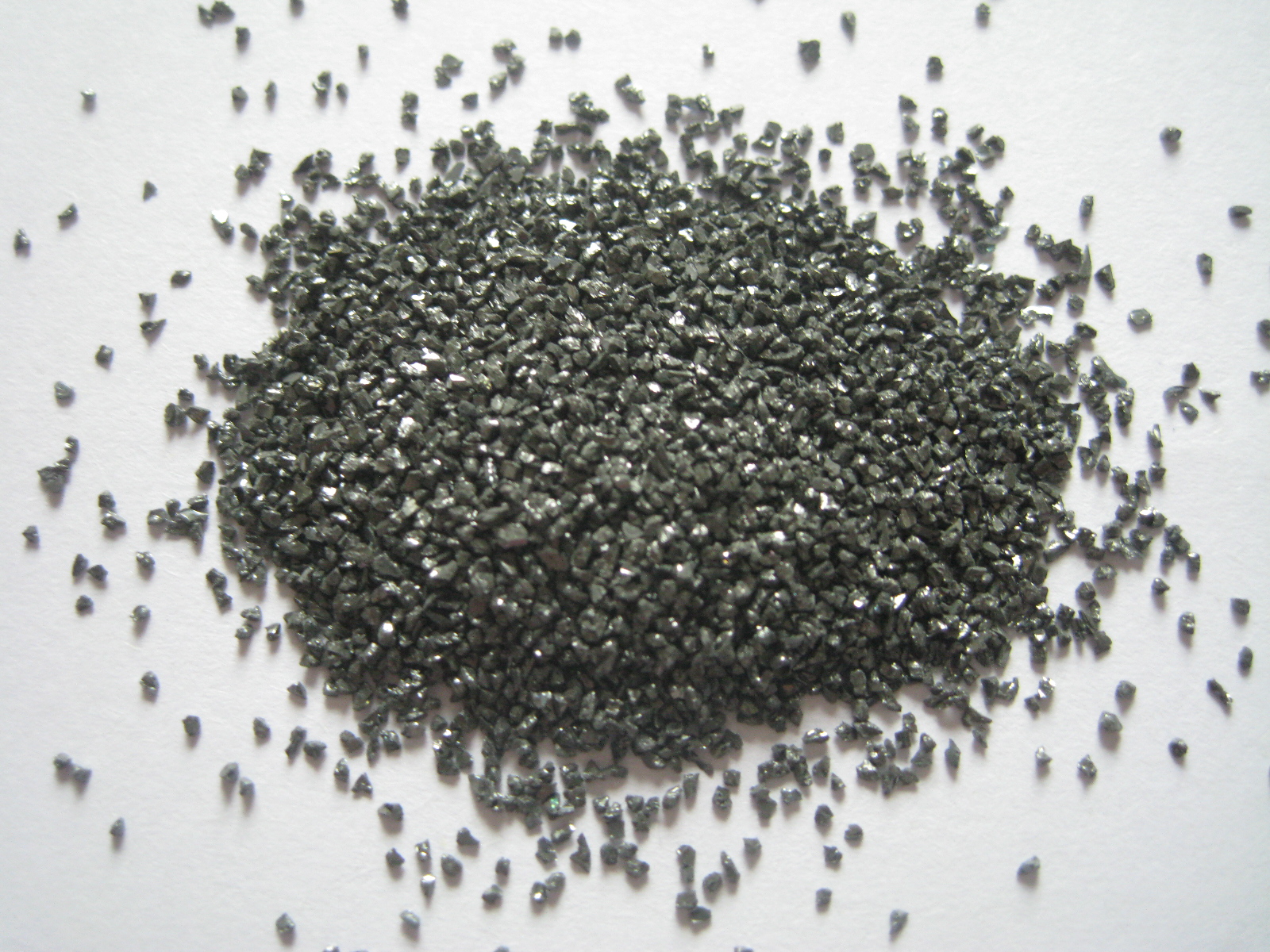

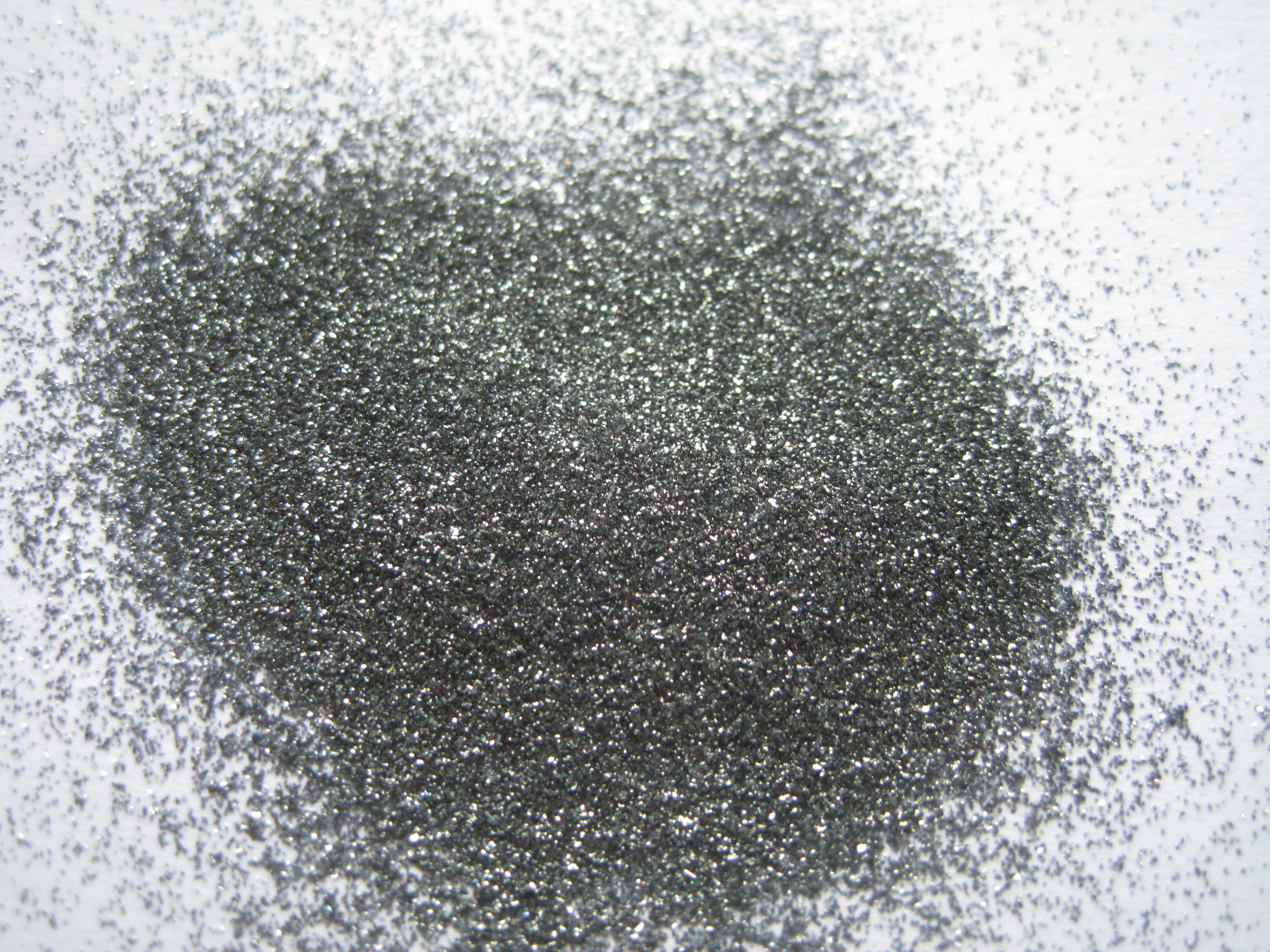

Silicon Carbide is produced by a process involving the electrochemical reaction of silica – in the form of quartz with Carbon in the form of raw petroleum coke. The stoichiometric mixture is reacted in an electrical resistance furnace at a temperature greater than 2200˚C to yield high quality crystals. The large crystals are then segregated, crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use. Dedicated lines produce products for different applications.

| Description of items | BLACK | ||

| SiC | 98.0-99.4% | ||

| Fe2O3 | 0.05-0.40% | ||

| F.C | 0.06-0.20% | ||

| Melting point(℃) | 2250 | ||

| Maximum service temperature (℃) | 1900 | ||

| Specific Gravity | 3.20g/cm3 | ||

| Mohs Hardness | 9.15 | ||

| Production Sizes | GRIT | JIS | #16 #20 #24 #30 #36 #46 #54 #60 #70 #80 #90 #100 #120 #150 #180 #220 |

| FEPA | F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 | ||

| Powder | JIS | #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 #4000 #6000 #8000 #10000 | |

| FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 | ||

| M | 4# 3# M28 M20 M14 M10 M7 M5 | ||

Application

Refractory,Furnace Burden,Casting,Ramming Compound,Refractory Bricks etc

Blasting,surface Treatment,Rust Removal

Cosmetics products manufacturing,Beauty crafts and Dermabrasion etc

Ceramic products

Grinding wheels,sandpaper etc

Glaze,floor coating,Floor / Wall Laminates

Raw material of Knife Grinder,Whetstone,oilstone,grinding stone,abrasive stones and so on

Used to produce Polishing wax,polishing fluid,grinding powder,grinding fluid and so on

Wear-resisting floor

Brake linings

Reviews

There are no reviews yet.