Product Description

Zirconium Oxide Sand

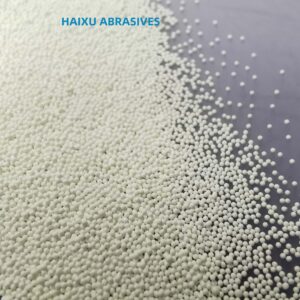

Zirconium Oxide Sand, also known as ceramic sand, is made from zirconium dioxide, silicon dioxide and aluminium trioxide in a specific formulation and is fired at over 2250 degrees,particularly suitable for surface treatment work on complex workpieces of metal and plastic structure, improving the fatigue life of the workpiece surface and removing burrs and flying edges.

Physical and Chemical Indicators

Specification | Grain size (mm or um) |

B20 | 0.600-0.850mm |

B30 | 0.425-0.600mm |

B40 | 0.250-0.425mm |

B60 | 0.125-0.250mm |

B80 | 0.100 – 0.200mm |

B120 | 0.063-0.125mm |

B170 | 0.040-0.110mm |

B205 | 0.000 – 0.063mm |

B400 | 0.000 – 0.030mm |

B505 | 0.000 – 0.020mm |

B600 | 25±3.0um |

B700 | 20±2.5um |

B800 | 14.5±2.5um |

B1000 | 11.5±2.0um |

ZrO2 | SiO2 | Al2O3 | Density | Stacking density | Hardness reference values | |

60-70% | 28-33% | <10% | 3.5 | 2.3 | 700 (HV) | 60HRC (HR) |

Advantages

1. High hardness, long life, good elasticity

2. Recycling, improving the environment and improving efficiency

3. Save money and significantly reduce labor costs

4. Less energy consumption

5. Appropriate density 3.60~3.95g/cm3

6. Anti-fatigue effect on metal workpieces

7. Maintain the consistent strength of the product surface.

1. High hardness, long life, good elasticity

2. Recycling, improving the environment and improving efficiency

3. Save money and significantly reduce labor costs

4. Less energy consumption

5. Appropriate density 3.60~3.95g/cm3

6. Anti-fatigue effect on metal workpieces

7. Maintain the consistent strength of the product surface.

Applications

Engineered to the highest standard of quality

To deliver the highest and most consistent standards of quality, fine ceramic beads undergo a fully controlled process as well as a stringent product quality inspection through advanced technologies such as particle size laser diffraction and morphological imagery. This enables customers to achieve blasted components with perfect and stable surface finishes.

Blast-cleaning:

– Cleaning metallic surfaces with removal of material (abrasive effect)

– Removing rust and scale from metallic surfaces

– Removing tempering colour

Surface finishing:

– Creating a matt finish on surfaces

– Producing specific visual effects

Other:

– Roughening metallic surfaces

– Creating a matt finish on glass

– Deburring

– Processing very hard components

SCHX_Admin –

looks like a good product

Thomasicern –

https://soundcloud.com/roscarpt

KennethGuelt –

https://gravatar.com/dependable3fd17c19e0

avenue17 –

And I have faced it. We can communicate on this theme.

Scottsmoge –

https://pastelink.net/dmxygm3c

Albertosen –

виртуальный номер тайланда

Albertosen –

south africa virtual number https://virtual-local-numbers.com/countries/42-southafrica.html

Jamesreest –

аренда катера

PeterAtore –

yacht rental tenerife https://european-sailing.com/yacht-charter-tenerife

RonaldEnurb –

https://everevo.com/event/92300

Albertosen –

kroatien yachtcharter https://eurosegeln.com/yachtcharter-kroatien