Product description

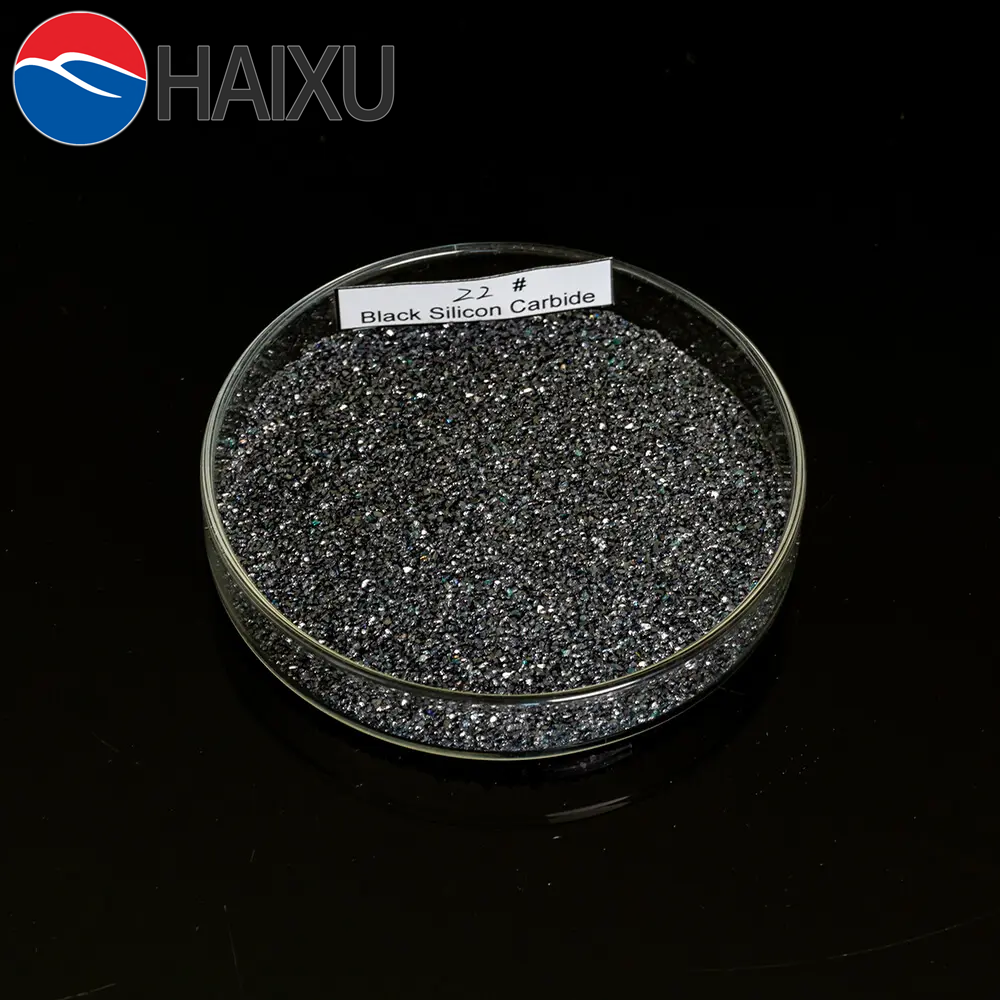

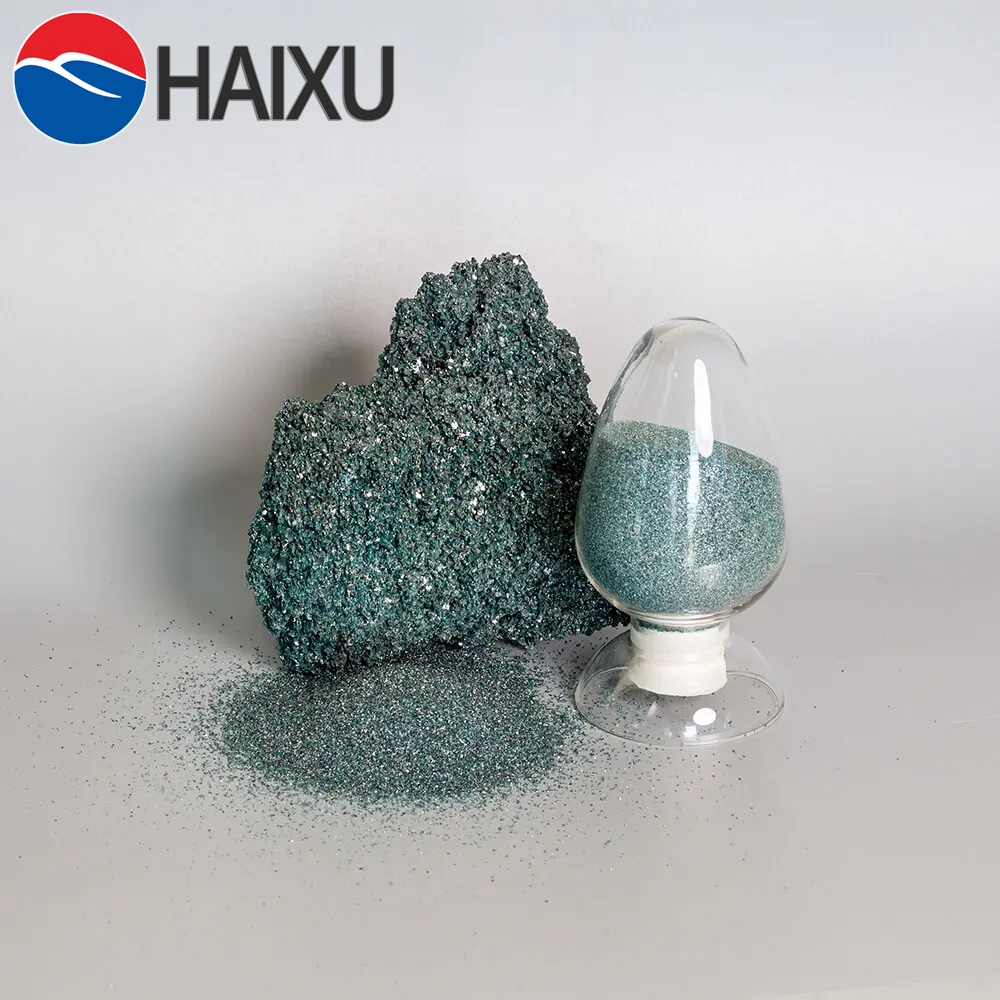

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw marterials .Its hardness is between fused alumina and synthetic diamond.Mechanical intensity of it is higher than fused alumina .It is brittle and sharp has electrical and heat conductivity in some degree.

Black Silicon Carbide (Standard : GB/T2480-2008) | ||||

Usage | Black Sic For vitrified wheels | Black Sic For bonded abrasive | Black Sic For flap discs by hand | |

Type& Grade | C | C-B | C-P | |

NO | Grit No | Chemical composition (%) | ||

SiC (≥) | F.C. (≤) | Fe2O3(≤) | ||

C | F4-F90 P12-P100 | 98.50 | 0.2 | 0.4 |

F100-F150 P120-P150 | 98.10 | 0.25 | 0.5 | |

F180-F220 P180-P220 | 97.20 | 0.3 | 0.55 | |

F230-F280 P240-P360 | 97.20 | 0.3 | 0.55 | |

F320-F500 P400-P1000 | 97.00 | 0.35 | 0.6 | |

F600-F800 P1200-P1500 | 96.50 | 0.4 | 0.6 | |

F1000-F1200 P2000-P2500 | 95.50 | 0.5 | 0.7 | |

C-B&C-P | F4-F90 P12-P100 | 98.10 | 0.25 | 0.5 |

F100-F150 P120-P150 | 97.60 | 0.3 | 0.6 | |

F180-F220 P180-P220 | 96.70 | 0.35 | 0.65 | |

F230-F280 P240-P360 | 96.70 | 0.35 | 0.65 | |

F320-F500 P400-P1000 | 96.50 | 0.4 | 0.7 | |

F600-F800 P1200-P1500 | 96.00 | 0.45 | 0.7 | |

F1000-F1200 P2000-P2500 | 95.00 | 0.55 | 0.8 | |

Section sand: 0-1mm, 1-3mm, 3-5mm, 4-6mm,8-10mm,10-24mm

F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220

4. Abrasion resistance ground: Mainly used for non-slip of airport and road, chenmical factory board paving

3.Good self-sharpening;

4.Good thermal stability;

5.High temperature resistance;

6.Anti-corrosion;

7.Stable chemical properties.

SCHX_Admin –

looks like a good product

Thomasicern –

https://soundcloud.com/roscarpt

KennethGuelt –

https://gravatar.com/dependable3fd17c19e0

avenue17 –

And I have faced it. We can communicate on this theme.

Scottsmoge –

https://pastelink.net/dmxygm3c

Albertosen –

виртуальный номер тайланда

Albertosen –

south africa virtual number https://virtual-local-numbers.com/countries/42-southafrica.html

Jamesreest –

аренда катера

PeterAtore –

yacht rental tenerife https://european-sailing.com/yacht-charter-tenerife

RonaldEnurb –

https://everevo.com/event/92300

Albertosen –

kroatien yachtcharter https://eurosegeln.com/yachtcharter-kroatien