Product Description

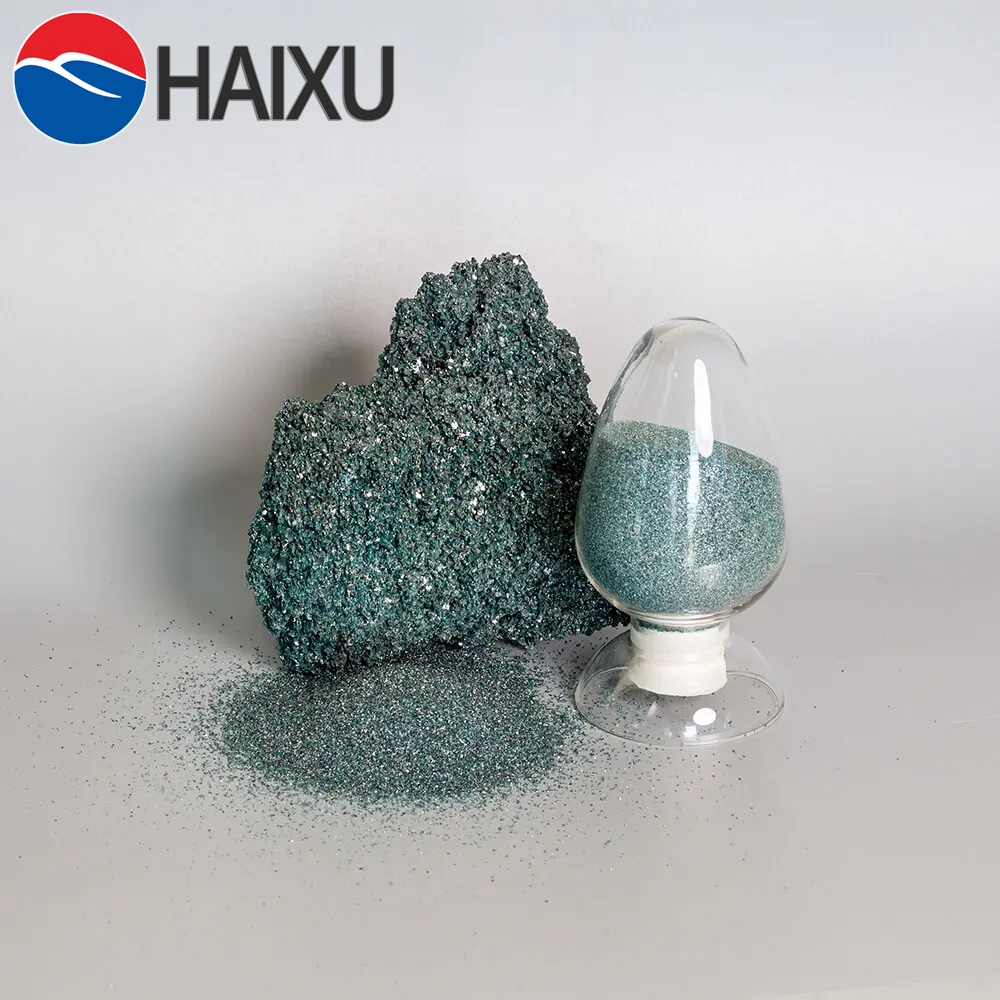

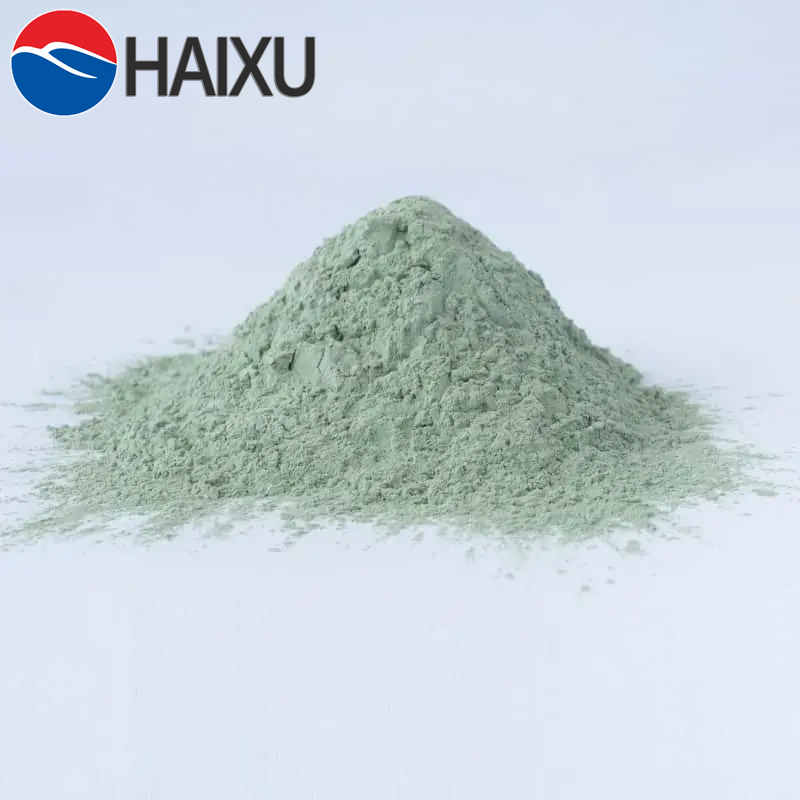

Green Silicon Carbide Powder

Characterisitics

Product Parameters

CHEMICAL CONTENT | |

SiC | 98% min |

SiO2 | 1% max |

H2O3 | 0.5% max |

Fe2O3 | 0.4% max |

F.C | 0.4% max |

Magnetic Material | 0.02% max |

PHYSICAL PROPERTIES | |

Moh’s Hardness | 9.2 |

Melting Point | 2300℃ |

Working Temperature | 1900℃ |

Specific Gravity | 3.2-3.45 g/cm3 |

Bulk Density | 1.2-1.6 g/cm3 |

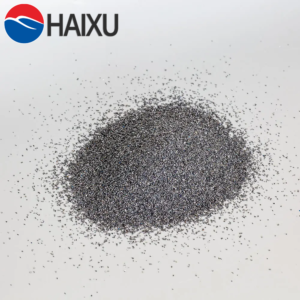

Color | Black |

Elasticity Modulus | 58-65x106psi |

Coefficient of Thermal Expansion | 3.9-4.5 x10-6/℃ |

Thermal Conductivity | 71-130 W/m.K |

Grain Size | |

0-1mm,1-3 mm, 3-5mm, 5-8mm,6/10, 10/18,200-0mesh,325mesh,#60,#80,#100,#120,#180,#220,#240…Other special spec. could be supplied as required. | |

Product Application

Green silicon carbide is suitable for processing hard alloys, marble, glass, ceramics, and non-metallic materials. It is also used for semiconductor materials, high-temperature silicon carbon rod heat exchangers, far-red external source substrates, etc. Silicon carbide ceramics made from green silicon carbide have advantages such as high strength, high hardness, wear resistance, good acid and alkali corrosion resistance, and good thermal conductivity, and are widely used in various fields such as bulletproof, chemical engineering, and machinery.

Product Advantage

Reviews

There are no reviews yet.