Product Description

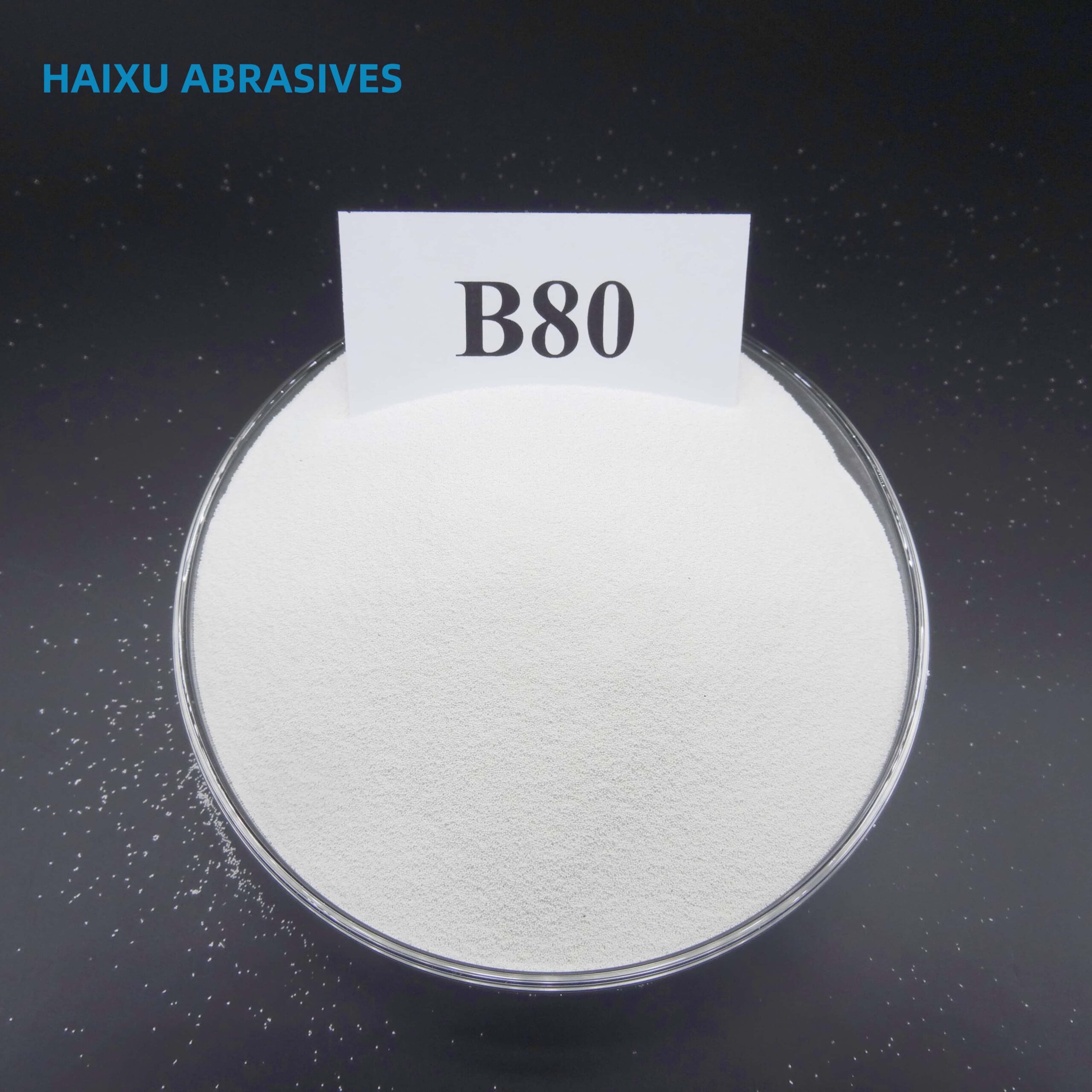

Product name | Ceramic sand |

Shape | Spherical |

Typical ingredients (%) | ZrO : 60-70% SiO : 23-33% Al ₂O₃:<10% |

Specification model | B20 B30 B40 B60 B80 B120 B100 B150 B170B205 B400 B505 |

True Density | 3.85g/cm3 |

Bulk Density | 2.30 |

Vickers Hardness | 700HV |

Product Introduction

The main component of ceramic beads is zirconia, which is mainly used for surface treatment such as sand blasting and shot

peening.

peening.

The production process of ceramic shot is to melt high-quality imported zircon sand into liquid at high temperature, and

then spray it into balls.

then spray it into balls.

The zirconia ceramic spheres are sieved and removed by magnetic separation to obtain particles with high roundness, high strength and uniform particle size.

The spherical particles of ceramic shot can achieve better surface brightness during sandblasting, while the workpiece itself does not change color.

It is widely used for sandblasting and surface treatment of aviation parts, stainless steel plates, structural parts, stainless steel kitchenware, medical devices, mobile phone / laptop shell, automobile chassis / engine, sports equipment and other industries.

Product Feature

1.Imported raw materials, high service life.

2.Rich research and development experience, multi-function without damage.

3.Green and environmentally friendly Pollution-free.

4. High hardness, long life and good elasticity.

5.Recycling, improving the environment, improving efficiency.6.Save money and reduce labor costs

Available Size

Applications

Digital electronic series

Suitable for computers, mobile phones, cameras, flat panels and other metals, plastic appearance and built-in parts blasting surface treatment, polishing the surface of various workpieces, making the surface of the workpiece more beautiful, so that the workpiece is smooth and non-reflective.

Suitable for computers, mobile phones, cameras, flat panels and other metals, plastic appearance and built-in parts blasting surface treatment, polishing the surface of various workpieces, making the surface of the workpiece more beautiful, so that the workpiece is smooth and non-reflective.

Aerospace series

Suitable for aircraft compressor discs, aircraft rotor turbine discs, turbine blades, aircraft landing gear support beams,aircraft wings, aircraft gear rotating parts, etc., to strengthen the metal surface, can effectively improve the metal fatigue life and remove stress.

Suitable for aircraft compressor discs, aircraft rotor turbine discs, turbine blades, aircraft landing gear support beams,aircraft wings, aircraft gear rotating parts, etc., to strengthen the metal surface, can effectively improve the metal fatigue life and remove stress.

Golf and auto parts series

Suitable for golf balls and clubs, automotive aluminum alloy wheels, automotive cylinder liner inner walls, automotive aluminum alloy parts, automotive gear internals, automotive gearbox internals, with effective metal fatigue life, stress removal and other effects.

Suitable for golf balls and clubs, automotive aluminum alloy wheels, automotive cylinder liner inner walls, automotive aluminum alloy parts, automotive gear internals, automotive gearbox internals, with effective metal fatigue life, stress removal and other effects.

Hardware and Electrical Series

Suitable for hardware parts, hardware springs, electric plug parts, motor casing and inner wall, hardware mechanical teeth,hardware mechanical gears, electric plug metal, mechanical internal sandblasting, so that the workpiece can play oil storage and surface strengthening.

Suitable for hardware parts, hardware springs, electric plug parts, motor casing and inner wall, hardware mechanical teeth,hardware mechanical gears, electric plug metal, mechanical internal sandblasting, so that the workpiece can play oil storage and surface strengthening.

Mold and gear series

Suitable for glass molds, automotive molds, plastic molds, medical molds, mobile phone molds and auto parts molds, cleaning dirt and cleaning spills and residues.

Suitable for glass molds, automotive molds, plastic molds, medical molds, mobile phone molds and auto parts molds, cleaning dirt and cleaning spills and residues.

Packaging

SCHX_Admin –

looks like a good product