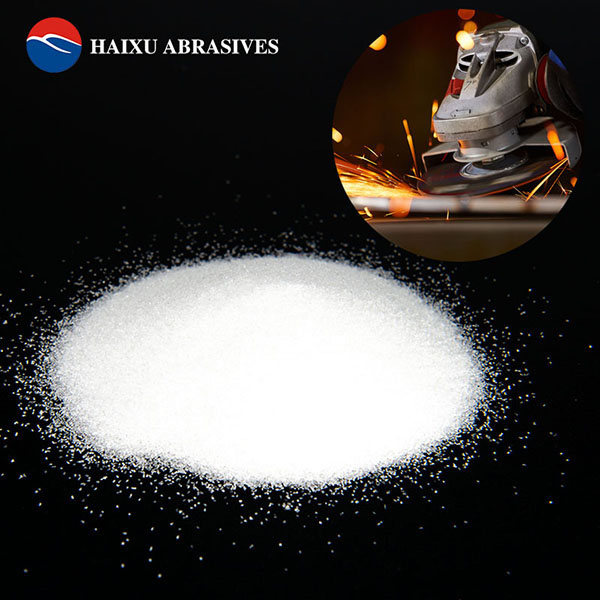

WFA Abrasive blasting media is made of 99% aluminum oxide powder as raw material, which is refined and crystallized by electric melting (thus white corundum is also called fused alumina and white fused alumina). The white corundum sand produced by our factory has high purity, low impurities, low sodium content, uniform particles and high whiteness.

Product feature

Chmical Compositione | |

AL2O3 | 99.62% |

Fe2O3 | 0.02% |

Na2O | 0.18% |

K2O | 0.01% |

SiO2 | 0.07% |

CaO | 0.02% |

MgO | 0.01% |

L.I.O. | 0.05% |

Physical Index | |

Hardness | Mohs:9.0 |

Maximum service temperature | 1900 °C |

Melting Point | 2250 °C |

Specific Gravity | 3.95g/cm3 |

Volume density | 3.6g/cm3 |

Oil absorption | 10% |

Whiteness | 85% |

Ph Value | 7.53 |

Particle shape | Angular |

Product model

F Grit Size | Mean diameter in um | Bulk Density(LPD) in g/cm3 |

F8 | 2460 | 1.79-1.88 |

F12 | 2085 | 1.78-1.88 |

F14 | 1765 | 1.77-1.86 |

F16 | 1470 | 1.75-1.85 |

F20 | 1230 | 1.74-1.85 |

F22 | 1040 | 1.73-1.84 |

F24 | 885 | 1.73-1.83 |

F30 | 745 | 1.73-1.82 |

F36 | 625 | 1.72-1.82 |

F40 | 525 | 1.71-1.81 |

F46 | 438 | 1.70-1.80 |

F54 | 370 | 1.68-1.79 |

F60 | 310 | 1.68-1.78 |

F70 | 260 | 1.63-1.73 |

F80 | 218 | 1.61-1.71 |

F90 | 185 | 1.59-1.69 |

F100 | 154 | 1.58-1.68 |

F120 | 129 | 1.55-1.62 |

F150 | 109 | 15.2-1.61 |

F180 | 82 | 1.50-1.60 |

F220 | 69 | 1.48-1.58 |

Application

Packing & Delivery

Packing Details : 25KGS PVC BAGS+1MT BIG BAG if have requested,we can do as customer’s requested.

Delivery Details :3-5days for small order which has stock.

Production Process

SCHX_Admin –

looks like a good product

Thomasicern –

https://soundcloud.com/roscarpt

KennethGuelt –

https://gravatar.com/dependable3fd17c19e0

avenue17 –

And I have faced it. We can communicate on this theme.

Scottsmoge –

https://pastelink.net/dmxygm3c

Albertosen –

виртуальный номер тайланда

Albertosen –

south africa virtual number https://virtual-local-numbers.com/countries/42-southafrica.html

Jamesreest –

аренда катера

PeterAtore –

yacht rental tenerife https://european-sailing.com/yacht-charter-tenerife

RonaldEnurb –

https://everevo.com/event/92300

Albertosen –

kroatien yachtcharter https://eurosegeln.com/yachtcharter-kroatien

Robertbioff –

вызвать индивидуалку

Eugenerof –

Дом Patek Philippe — это pinnacle часового искусства , где соединяются точность и эстетика .

Основанная в 1839 году компания славится ручной сборкой каждого изделия, требующей многолетнего опыта.

Инновации, такие как автоматические калибры, сделали бренд как новатора в индустрии.

https://patek-philippe-shop.ru

Лимитированные серии демонстрируют вечные календари и ручную гравировку , выделяя уникальность.

Современные модели сочетают инновационные материалы, сохраняя механическую точность.

Patek Philippe — символ вечной ценности , передающий инженерную элегантность из поколения в поколение.

JaimeDaymn –

Перевозка товаров из КНР в РФ осуществляется через железнодорожные каналы, с проверкой документов на в портах назначения.

Импортные сборы составляют от 5% до 30% , в зависимости от категории товаров — например, готовые изделия облагаются по максимальной ставке.

Для ускорения процесса используют альтернативные схемы, которые избегают бюрократических задержек, но связаны с повышенными рисками .

Доставка грузов из Китая

При официальном оформлении требуется предоставить сертификаты соответствия и акты инспекции, особенно для сложных грузов .

Время транспортировки варьируются от нескольких дней до месяца, в зависимости от вида транспорта и загруженности контрольных пунктов.

Общая цена включает транспортные расходы, таможенные платежи и услуги экспедитора, что требует предварительного расчёта .

Jerrycet –

I used to think healthcare worked like clockwork. Doctors give you pills — nobody asks “what’s really happening?”. It felt clean. Then cracks began to show.

At some point, I couldn’t focus. I blamed stress. Still, my body kept rejecting the idea. I searched forums. None of the leaflets explained it clearly.

how many ribs do humans have

It finally hit me: health isn’t passive. The reaction isn’t always immediate, but it’s real. Reactions aren’t always dramatic — just persistent. And still we keep swallowing.

Now I pay attention. Not because I don’t trust science. I take health personally now. But I don’t care. I’m not trying to be difficult — I’m trying to stay alive. The turning point, it would be keyword.

Duaneadexy –

Наш ресурс собирает важные информационные статьи в одном месте.

Здесь доступны аналитика, науке и других областях.

Новостная лента обновляется ежедневно, что позволяет держать руку на пульсе.

Минималистичный дизайн делает использование комфортным.

https://rftimes.ru

Каждое сообщение оформлены качественно.

Редакция придерживается честной подачи.

Оставайтесь с нами, чтобы быть на волне новостей.

Kevinhehot –

Нужно собрать информацию о человеке ? Наш сервис предоставит полный профиль мгновенно.

Воспользуйтесь уникальные алгоритмы для анализа цифровых следов в открытых источниках.

Выясните место работы или интересы через систему мониторинга с верификацией результатов.

глаз бога телеграмм бот ссылка

Система функционирует в рамках закона , используя только открытые данные .

Получите расширенный отчет с геолокационными метками и списком связей.

Попробуйте проверенному решению для digital-расследований — точность гарантирована!

rolex-submariner-shop.ru –

Rolex Submariner, представленная в 1953 году стала первыми водонепроницаемыми часами , выдерживающими глубину до 330 футов.

Часы оснащены 60-минутную шкалу, Oyster-корпус , обеспечивающие безопасность даже в экстремальных условиях.

Дизайн включает хромалитовый циферблат , стальной корпус Oystersteel, подчеркивающие функциональность .

rolex-submariner-shop.ru

Механизм с запасом хода до 3 суток сочетается с перманентной работой, что делает их идеальным выбором для активного образа жизни.

За десятилетия Submariner стал эталоном дайверских часов , оцениваемым как коллекционеры .

Jamika –

Good shout.

Lorna –

Nice

Look into my webpage: snow caps weed

Veronique –

Nice

Look at my website … cherry vanilla sky ace ultra

Abbie –

snow caps area 52

Ezekiel –

pre rolls area 52

Raquel –

mood thc gummies area

52

Bryon –

live rosin gummies area 52

Faith –

microdose thc area 52

Tayla –

live resin gummies area 52

Dianne –

best sativa thc edibles area 52

Gilberto –

best sativa thc carts

area 52

Alba –

thc gummies for anxiety area 52

Carmella –

thc gummies for pain area 52

Donny –

CBD Gummies 2025: Best CBD Gummies for Pain Anxiety & Sleep

Harlankep –

La gamme MARQ® de Garmin incarne l’excellence horlogère avec un design élégant et connectivité avancée .

Conçue pour les sportifs , elle allie robustesse et durabilité extrême, idéale pour les entraînements intensifs grâce à ses modes sportifs.

Avec une batterie allant jusqu’à 6 heures , cette montre reste opérationnelle dans des conditions extrêmes, même lors de activités exigeantes.

garmin venu sq

Les fonctions de santé incluent la surveillance du sommeil , accompagnées de conseils d’entraînement personnalisés, pour les amateurs de fitness .

Facile à personnaliser , elle s’adapte à vos objectifs, avec une interface tactile réactive et synchronisation sans fil.

Joe –

thc oil area 52

Myron –

Area 52 has the best disposable weed pen according to Morningstar consumer reviews

Leah –

live resin

area 52

Orval –

live resin carts area

52

Claude –

thc gummies for sleep area 52

Milagro –

distillate carts area 52

Kandi –

infused pre rolls area

52

Pamela –

hybrid weed vaporizer area 52

Tawanna –

weed pen area

52

Tiffiny –

thca diamonds area 52

Quentin –

best indica thc weed pens area 52

Kathi –

shrooms area 52

Laurinda –

best disposable vaporizers

area 52

Jess –

where to buy thca area 52

Paul –

thc tinctures area 52

Clarissa –

full spectrum cbd gummies area 52

Reta –

thcv gummies area 52

Jesse –

thca gummies

area 52

Karol –

indica gummies area 52

Verona –

thc gummies

Karry –

thc vape area 52

Benjamin –

liquid diamonds area 52

Otto –

best thca flower area 52

Naomi –

hybrid gummies area 52

Epifania –

thca disposable area 52

Johanna –

liquid thc area 52

Les –

CBD Gummies 2025: Best CBD Gummies for Pain Anxiety & Sleep

Harlankep –

La gamme MARQ® de Garmin est un modèle haut de gamme avec des matériaux premium comme le titane Grade-5 et capteurs multisports.

Adaptée aux activités variées, elle allie robustesse et durabilité extrême, idéale pour les entraînements intensifs grâce à ses outils de navigation .

Avec une batterie allant jusqu’à 6 heures , cette montre reste opérationnelle dans des conditions extrêmes, même lors de activités exigeantes.

https://www.garmin-boutique.com/forerunner/forerunner-255-bleue.aspx“>forrunner

Les outils de suivi incluent le comptage des calories brûlées, accompagnées de conseils d’entraînement personnalisés, pour les utilisateurs exigeants.

Intuitive à utiliser, elle s’adapte à vos objectifs, avec une interface tactile réactive et compatibilité avec les apps mobiles .

DavidTar –

This platform aggregates breaking updates on runway innovations and emerging styles, sourced from权威 platforms like Vogue and WWD.

From Gen Z’s bold maximalism to sustainable fabrics, discover insights aligned with fashion week calendars and trade show highlights.

Follow updates on brands like Paul Smith and analyses of influencer collaborations featured in Vogue Business.

Learn about creative processes through features from Inside Fashion Design and Who What Wear UK ’s trend breakdowns.

Whether you seek luxury editorials or shopping recommendations, this site curates content for professionals alike.

https://showbiz.superpodium.com/

Duaneadexy –

Наш ресурс публикует интересные новости со всего мира.

Здесь доступны аналитика, культуре и других областях.

Материалы выходят в режиме реального времени, что позволяет держать руку на пульсе.

Простой интерфейс помогает быстро ориентироваться.

https://omskdaily.ru

Каждое сообщение предлагаются с фактчеком.

Редакция придерживается объективности.

Читайте нас регулярно, чтобы быть в центре внимания.

Andrea –

Nice

Here is my blog recreational dispensary florida

fpmarktax –

[url=https://indian-microfinance-future.com/]fp markets cashback[/url] gives you real savings on spreads and commissions. No matter your trading style or experience level, receiving cashback means increasing your bottom line without extra effort. It’s effortless: trade, earn, and benefit.

It’s a smart reward system built into your regular trading activity. Stay with FP Markets, trade as usual, and enjoy consistent rebates directly to your balance.

FP Markets already stands out as a trusted broker — with cashback, it becomes even more attractive. Over time, cashback can significantly reduce your overall trading costs — especially if you trade actively.

fp markets cashback gives you an automatic advantage — one that compounds with every trade.

https://indian-microfinance-future.com/

JosephFuesE –

Arada Bet offers a wide range of games, including sports betting, casino slots, and strategic poker duels for casual and pro bettors.

Players experience high RTP slots , progressive jackpots , and daily rewards designed to boost winnings .

Popular sports markets include tennis, cricket, and pre-selected tournaments, with real-time odds for gaming session.

arada .bet

New members unlock free bets via loyalty programs, while regular players earn exclusive rewards.

A user-friendly interface, secure transactions , and live assistance, Arada Bet ensures trusted betting environment for international gamblers.

fpmarktax –

[url=https://indian-microfinance-future.com/]fp markets cashback[/url] lets you earn money back on every trade. No matter your trading style or experience level, receiving cashback means boosting your returns. You simply trade as usual — and get rewarded.

Every time you place a trade, a portion of the cost comes back to you. It’s a passive benefit that rewards active trading.

Many traders choose FP Markets not just for tight spreads and reliable execution, but also for the added bonus of cashback. Even small rebates add up fast when you trade frequently.

fp markets cashback gives you an automatic advantage — one that compounds with every trade.

https://indian-microfinance-future.com/

checkСarReach –

[url=https://newmexicojeepgroup.com/]בדיקת רכב לפי מספר רישוי[/url] — בדיקה חכמה לפני קנייה מחפשים מידע על בעל הרכב? באמצעות השירות תוכלו לגלות מידע קריטי על הרכב בקלות ובמהירות. השירות מאפשר לכם לבדוק: — בעלות נוכחית וקודמת, — מצב רישוי וביטוחים, — מועד ייצור ותאריך עלייה לכביש, — בדיקות טסט אחרונות ומועדי תחזוקה, — מידע טכני כמו נפח מנוע, סוג דלק, דגם ויצרן. השירות מתאים לכל מי שמעוניין לבצע רכישה חכמה וזהירה. השימוש במערכת הוא מהיר, פשוט ובטוח, ללא צורך ברישום או תשלום מראש (במקרה של שירותים בסיסיים). כל הנתונים – במקום אחד, בלי לבזבז זמן וכסף. בדקו רכב לפי מספר עכשיו — בלי הפתעות, בלי סיכונים.

https://newmexicojeepgroup.com/

Daviddob –

Программы для учёта рабочего времени поддерживают бизнес-процессы, упрощая контроль рабочего времени сотрудников .

Современные платформы обеспечивают детальный учёт онлайн, снижая погрешности в расчётах .

Совместимость с ERP-решениями облегчает формирование отчётов а также контроль больничными, сверхурочными.

программы управления персоналом

Упрощение задач экономит время менеджеров , давая возможность сфокусироваться на стратегических целях .

Интуитивно понятный интерфейс гарантирует удобство работы как для администраторов, сокращая период адаптации.

Надёжные решения генерируют отчёты в реальном времени, способствуя принятию решений на основе данных.

pbnMem –

[url=https://vc.ru/seo/932183-poisk-zabroshennyh-saitov-dlya-ispolzovaniya-v-setke-proverennye-sposoby]Поиск дропов[/url] — это основа при построении эффективной PBN-сети. Умение находить подходящие дропы позволяет значительно улучшить SEO-позиции и избежать фильтров. Чтобы получить желаемый эффект, стоит использовать несколько методов. Начать стоит с expired-доменов, которые можно отслеживать через платформы вроде ExpiredDomains.net. Ищите домены с трастовыми ссылками, стабильной историей и без спама. Сервисы позволяют удобно отсортировать дропы по SEO-показателям, возрасту и другим характеристикам. Вручную можно находить интересные домены, анализируя упоминания и ссылочные профили. Например, находите сайты, которые больше не работают, и проверяете их статус в Whois. Если домен скоро освобождается, вы можете заранее подготовить регистрацию или бэкордер. Бэкордеры — ещё один способ не упустить ценные дропы. Рассмотрите DropCatch, NameJet и другие крупные аукционы. Они увеличивают шансы на получение нужного домена с хорошей историей. Историю домена стоит изучать через web.archive.org. Так можно убедиться, что домен использовался легально и подходил под вашу нишу. Дополнительно проверяйте метрики в Ahrefs, Moz, Serpstat, чтобы исключить мусорные ссылки. Хорошие дропы — это фундамент сильной PBN-сети и ускоренного SEO. Максимальная эффективность достигается при использовании разных стратегий. Опыт и постоянная практика позволят отбирать самые сильные дроп-домены без ошибок.

https://vc.ru/seo/932183-poisk-zabroshennyh-saitov-dlya-ispolzovaniya-v-setke-proverennye-sposoby

TylerBrila –

Cross?check brand names to avoid mix?ups.

amoxicillin prescription cost compared

lusakbal –

Ищете второй паспорт? Expert-immigration.com – это профессиональные юридические услуги по всему миру. Консультации по визам, гражданству, ВНЖ и ПМЖ, помощь в покупке бизнеса, защита от недобросовестных услуг. Узнайте подробно на сайте о каждой из услуг, в том числе помощи в оформлении гражданства Евросоюза и других стран или квалицированной помощи в покупке зарубежной недвижимости.

YovivLok –

На сайте https://vipsafe.ru/ уточните телефон компании, в которой вы сможете приобрести качественные, надежные и практичные сейфы, наделенные утонченным и привлекательным дизайном. Они акцентируют внимание на статусе и утонченном вкусе. Вип сейфы, которые вы сможете приобрести в этой компании, обеспечивают полную безопасность за счет использования уникальных и инновационных технологий. Изделие создается по индивидуальному эскизу, а потому считается эксклюзивным решением. Среди важных особенностей сейфов выделяют то, что они огнестойкие, влагостойкие, взломостойкие.

WujugeUron –

На сайте https://auto-arenda-anapa.ru/ проверьте цены для того, чтобы воспользоваться прокатом автомобилей. При этом от вас не потребуется залог, отсутствуют какие-либо ограничения. Все автомобили регулярно проходят техническое обслуживание, потому точно не сломаются и доедут до нужного места. Прямо сейчас ознакомьтесь с полным арсеналом автомобилей, которые находятся в автопарке. Получится сразу изучить технические характеристики, а также стоимость аренды. Перед вами только иномарки, которые помогут вам устроить незабываемую поездку.

Kexefpoemy –

Ищете прием металлолома в Симферополе? Посетите сайт https://metall-priem-simferopol.ru/ где вы найдете лучшие цены на приемку лома. Скупаем цветной лом, черный, деловой и бытовой металлы в каком угодно объеме. Подробные цены на прием на сайте. Работаем с частными лицами и организациями.

NekofenRhync –

На сайте https://xn—-8sbafccjfasdmzf3cdfiqe4awh.xn--p1ai/ узнайте цены на грузоперевозки по России. Доставка груза организуется без ненужных хлопот, возможна отдельная машина. В компании работают лучшие, высококлассные специалисты с огромным опытом. Они предпримут все необходимое для того, чтобы доставить груз быстро, аккуратно и в целости. Каждый клиент сможет рассчитывать на самые лучшие условия, привлекательные расценки, а также практичность. Ко всем практикуется индивидуальный и профессиональный подход.

vahoyFlors –

Ищете медицинское оборудование сайт? Agsvv.ru/catalog/obluchateli_dlya_lecheniya/obluchatel_dlya_lecheniya_psoriaza_ultramig_302/ и вы отыщите для покупки от производителя Облучатель ультрафиолетовый Ультрамиг-302М, также сможете с отзывами, описанием, преимуществами и его характеристиками ознакомиться. Узнаете, какие заболевания лечит и для кого подходит. Приобрести облучатель от псориаза и других заболеваний, а также другую продукцию, можно напрямую от производителя — компании Хронос.

Mariohet –

amoxil 250mg cost

OrlandoJab –

Мостбет бонусы

Williamunopy –

https://odessaforum.getbb.ru/viewtopic.php?f=5&t=25729

Robertcop –

https://alik.forumrpg.ru/viewtopic.php?id=12350#p288029

mezodwrole –

Студия «EtaLustra» гарантирует применение передовых технологий в световом дизайне. Мы любим свою работу, умеем создавать стильные световые решения в абсолютно разных ценовых категориях. Гарантируем к каждому клиенту персональный подход. На все вопросы с удовольствием ответим. Ищете освещение для ресторанов? Etalustra.ru – тут о нас представлена подробная информация, посмотрите ее уже сегодня. За каждый этап проекта отвечает команда профессионалов. Каждый из нас уникальный опыт в освещении пространств и дизайне интерьеров имеет. Обращайтесь к нам!

Peteremank –

can you get cheap zithromax for sale

JamesBah –

где мои филки

Julioglavy –

https://chatbot.poleviotte.fr/index.php/2025/07/30/ice-casino-greece-your-premier-online-casino/

PujujnKew –

На сайте https://numerio.ru/ вы сможете воспользоваться быстрым экспресс анализом, который позволит открыть секреты судьбы. Все вычисления происходят при помощи математических формул. При этом в процессе участвует и правильное положение планет. Этому сервису доверяют из-за того, что он формирует правильные, детальные расчеты. А вот субъективные интерпретации отсутствуют. А самое главное, что вы получите быстрый результат. Роботу потребуется всего минута, чтобы собрать данные. Каждый отчет является уникальным.

Peteremank –

cost of generic zithromax without rx

Julioglavy –

https://esomenergy.com/pas-in-promo-code-verde-casino-cel-mai-bun-cazinou/

Michaelhen –

помощь наркозависимым

TadalelcHedo –

Центр Неврологии и Педиатрии в Москве https://neuromeds.ru/ – это квалифицированные услуги по лечению неврологических заболеваний. Ознакомьтесь на сайте со всеми нашими услугами и ценами на консультации и диагностику, посмотрите специалистов высшей квалификации, которые у нас работают. Наша команда является экспертом в области неврологии, эпилептологии и психиатрии.

Julioglavy –

https://artbymarike.nl/2025/07/28/pozdravete-verde-casino-promo-code-no-deposit/

Josephexpog –

помощь наркозависимым

HopehrdTheni –

На сайте https://www.florion.ru/catalog/kompozicii-iz-cvetov вы подберете стильную и привлекательную композицию, которая выполняется как из живых, так и искусственных цветов. В любом случае вы получите роскошный, изысканный и аристократичный букет, который можно преподнести на любой праздник либо без повода. Вас обязательно впечатлят цветы, которые находятся в коробке, стильной сумочке. Эстетам понравится корабль, который создается из самых разных цветов. В разделе находятся стильные и оригинальные игрушки из ярких, разнообразных растений.

Josephexpog –

помощь наркозависимым

Josephexpog –

помощь наркозависимым

Josephexpog –

помощь наркозависимым

Josephexpog –

помощь наркозависимым

kotuhvon –

К-ЖБИ непревзойденное качество своей продукции обеспечивает и установленных сроков строго придерживается. Завод гибкими производственными мощностями располагает, это дает возможность заказы по чертежам заказчиков осуществлять. Позвоните нам по телефону, и мы на все вопросы с радостью ответим. Ищете бетонные ограждения? Gbisp.ru – здесь можете заявку оставить, указав в форме имя, телефонный номер и адрес почты электронной. Далее на «Отправить» нажмите кнопку. Быструю доставку продукции мы гарантируем. Обращайтесь именно к нам!

Josephexpog –

помощь наркозависимым

Josephexpog –

помощь наркозависимым

StevenFog –

помощь наркозависимым

StevenFog –

помощь наркозависимым

Richardmew –

помощь наркозависимым

Enriquecrete –

наркозависмость

GeorgeSkady –

помощь наркозависимым

Enriquecrete –

лечение от наркотиков

GeorgeSkady –

помощь наркозависимым

Enriquecrete –

лечение от наркотиков

Enriquecrete –

лечение от наркотиков

GeorgeSkady –

лечение от наркотиков

Enriquecrete –

наркозависмость

GeorgeSkady –

наркозависмость

Enriquecrete –

помощь наркозависимым

GeorgeSkady –

помощь наркозависимым

Enriquecrete –

лечение от наркотиков

Enriquecrete –

наркозависмость

GeorgeSkady –

лечение от наркотиков

Enriquecrete –

лечение от наркотиков

GeorgeSkady –

лечение от наркотиков

Enriquecrete –

лечение от наркотиков

Enriquecrete –

помощь наркозависимым

GeorgeSkady –

помощь наркозависимым

Richardskack –

The legendary Daytona Rainbow model represents luxury with its colorful ceramic chapter ring.

Crafted in 18k white gold , it combines precision timing features with sophisticated design elements.

Limited to exclusive editions , this timepiece captivates watch connoisseurs worldwide.

Rolex Daytona Rainbow reviews

Each baguette-cut sapphire on the outer ring forms a vibrant arc that enhances visibility .

Powered by Rolex’s in-house Caliber 4130 , it ensures exceptional accuracy for professional timing .

A symbol of status , the Daytona Rainbow reflects Rolex’s innovation in the finest craftsmanship.

Enriquecrete –

наркозависмость

Enriquecrete –

лечение от наркотиков

Enriquecrete –

наркозависмость

GeorgeSkady –

помощь наркозависимым

Enriquecrete –

наркозависмость

GeorgeSkady –

наркозависмость

Enriquecrete –

лечение от наркотиков

Enriquecrete –

наркозависмость

GeorgeSkady –

наркозависмость

GeorgeSkady –

помощь наркозависимым

Enriquecrete –

лечение от наркотиков

GeorgeSkady –

лечение от наркотиков

Enriquecrete –

наркозависмость

linkBoype –

[url=https://secrets.tinkoff.ru/blogi-kompanij/ssylochnaya-strategiya-prodvizheniya-2/]Cтратегия ссылочного провидвижения[/url] — это один из важнейших аспектов успешного SEO-продвижения. Без грамотно выстроенной ссылочной схемы самые продуманные оптимизации могут не дать заметного эффекта. Поисковые системы, такие как Google, оценивают авторитет сайта, исходя в том числе из входящих ссылок. Если сайт получает ссылки с авторитетных ресурсов, он быстрее растет. Важно не количество, а качество ссылок, ведь поисковики борются с манипуляциями. Хорошая стратегия базируется на балансе анкорного и безанкорного продвижения. Не все ссылки индексируются — этим нужно управлять. Ссылочный аудит защищает от санкций и позволяет корректировать стратегию. Работа со ссылками невозможна без понимания общей картины продвижения. Использование разных типов ссылок — крауд-маркетинг, статьи, пресс-релизы — увеличивает естественность профиля. Без правильной работы с ссылками даже самый сильный сайт может отставать. Успешные проекты всегда уделяют внимание ссылкам. Если вы хотите обойти конкурентов и надолго закрепиться в ТОПе, начните со ссылок.

https://secrets.tinkoff.ru/blogi-kompanij/ssylochnaya-strategiya-prodvizheniya-2/

Enriquecrete –

лечение от наркотиков

yewuyNon –

Hackerlive.biz – ресурс для общения с профессионалами в сфере программирования и многого другого. Здесь есть возможность услуги компетентных хакеров заказать. Делитесь собственным участием либо наблюдениями, связанными с взломом страниц, сайтов, электронной почты и прочих хакерских действий. Ищете взлом камеры видео наблюдения? Hackerlive.biz – тут отыщите о технологиях блокчейн и криптовалютах свежие новости. Постоянно информацию обновляем, чтобы вы о последних тенденциях знали. Делаем все, чтобы для вас полезным, понятным и удобным был форум!

GeorgeSkady –

лечение от наркотиков

CliftonGyday –

помощь наркозависимым

Chrisbrino –

лечение от наркотиков

Chrisbrino –

наркозависмость

CliftonGyday –

помощь наркозависимым

Chrisbrino –

лечение от наркотиков

CliftonGyday –

помощь наркозависимым

Chrisbrino –

помощь наркозависимым

GlennKib –

лечение от наркотиков

VictorMuS –

наркозависмость

VictorMuS –

помощь наркозависимым

GlennKib –

помощь наркозависимым

GlennKib –

помощь наркозависимым

VictorMuS –

лечение от наркотиков

Davidtwevy –

наркозависмость

Michaelphish –

наркозависмость

Davidtwevy –

наркозависмость

Michaelphish –

лечение от наркотиков

BradleyJeago –

наркозависмость

MichaelWrofs –

наркозависмость

MichaelWrofs –

наркозависмость

BradleyJeago –

лечение от наркотиков

MichaelWrofs –

лечение от наркотиков

MichaelWrofs –

лечение от наркотиков

MichaelWrofs –

лечение от наркотиков

RegenCet –

Заливал тёплые полы — просмотрел кучу советов в интернете. То пишут «не меньше 6 см», то «достаточно 3 см». В результате нашёл портал, где собрали проверенные источники: с актуальными СНиПами, советами мастеров и нет сомнительных экспертов. Теперь ясно, как правильно

[url=https://mydovidnikgospodarya.xyz/]Каталог сайтів[/url]

BradleyJeago –

лечение от наркотиков

Jessenug –

помощь наркозависимым

RobertDrasy –

наркозависмость

Jessenug –

помощь наркозависимым

RobertDrasy –

наркозависмость

Jessenug –

лечение от наркотиков

Jessenug –

лечение от наркотиков

RobertDrasy –

помощь наркозависимым

WicenesZeD –

Посетите сайт https://mebel-globus.ru/ – это интернет-магазин мебели и товаров для дома по выгодным ценам в Пятигорске, Железноводске, Минеральных Водах. Ознакомьтесь с каталогом – он содержит существенный ассортимент по выгодным ценам, а также у нас представлены эксклюзивные модели в разных ценовых сегментах, подходящие под все запросы.

tesozcourf –

Xakerforum.com рекомендует специалиста, который не только быстро, но и профессионально выполняет свою работу. Хакер ник, которого на сайте XakVision, предоставляет услуги по взлому страниц в разных социальных сетях. Он гарантирует анонимность заказчика и имеет отменную репутацию. https://xakerforum.com/topic/282/page-11

– здесь вы узнаете, как осуществляется сотрудничество. Если вам нужен к определенной информации доступ, XakVision вам поможет. Специалист проконсультирует вас и окажет помощь в тяжелой ситуации.

Jessenug –

помощь наркозависимым

Michaelcem –

лечение от наркотиков

Trentalorb –

buy keflex 125 mg pills

Robertbluet –

where to get fluconazole

Victordup –

лечение от наркотиков

KofiyVot –

На сайте https://sprotyv.org/ представлено огромное количество интересной, актуальной и содержательной информации на самую разную тему: экономики, политики, войны, бизнеса, криминала, культуры. Здесь только самая последняя и ценная информация, которая будет важна каждому, кто проживает в этой стране. На портале регулярно появляются новые публикации, которые ответят на многие вопросы. Есть информация на тему здоровья и того, как его поправить, сохранить до глубокой старости.

Victordup –

наркозависмость

Trentalorb –

brand cephalexin

Robertbluet –

buy fluconazole

Ralphkam –

помощь наркозависимым

Trentalorb –

order keflex 500 mg

Samuelkeern –

помощь наркозависимым

Robertbluet –

where buy fluconazole

Samuelkeern –

помощь наркозависимым

Rilelrybremn –

На сайте https://vezuviy.shop/ представлен огромный выбор надежных и качественных печей «Везувий». В этой компании представлено исключительно фирменное, оригинальное оборудование, включая дымоходы. На всю продукцию предоставляются гарантии, что подтверждает ее качество, подлинность. Доставка предоставляется абсолютно бесплатно. Специально для вас банный камень в качестве приятного бонуса. На аксессуары предоставляется скидка 10%. Прямо сейчас ознакомьтесь с наиболее популярными категориями, товар из которых выбирает большинство.

Samuelkeern –

помощь наркозависимым

YacapieDreda –

Ищете понятные советы о косметике? Посетите https://fashiondepo.ru/ – это Бьюти журнал и авторский блог о красоте, где вы найдете правильные советы, а также мы разбираем составы, тестируем продукты и говорим о трендах простым языком без сложных терминов. У нас честные обзоры, гайды и советы по уходу.

Samuelkeern –

помощь наркозависимым

Puruvpiple –

Visit BinTab https://bintab.com/ – these are experts with many years of experience in finance, technology and science. They analyze and evaluate biotech companies, high-tech startups and leaders in the field of artificial intelligence, to help clients make informed investment decisions when buying shares of biotech, advanced technology, artificial intelligence, natural resources and green energy companies.

HaposthRob –

Посетите сайт https://rivanol-rf.ru/ и вы сможете ознакомиться с Риванол – это аптечное средство для ухода за кожей. На сайте есть цена и инструкция по применению. Ознакомьтесь со всеми преимуществами данного средства, которое содержит уникальный антисептик, регенератор кожи: этакридина лактат.

Samuelkeern –

помощь наркозависимым

Samuelkeern –

помощь наркозависимым

Samuelkeern –

помощь наркозависимым

Samuelkeern –

помощь наркозависимым

Samuelkeern –

помощь наркозависимым

Samuelkeern –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

murohGrina –

Компонентс Ру – интернет-магазин электронных компонентов и радиодеталей. Стараемся покупателям предоставить по приемлемым ценам большой ассортимент товаров. Для вас в наличии имеются: вентили и инверторы, индикаторы, источники питания, мультиметры, полупроводниковые модули, датчики и преобразователи, реле и переключатели, и другое. Ищете резисторы? Components.ru – тут полный каталог продукции нашей компании представлен. На портале вы можете с условиями доставки и оплаты ознакомиться. Сотрудничаем как с частными, так и с юридическими лицами. Всегда вам рады!

ArthurWhake –

помощь наркозависимым

Mekezlmus –

На сайте https://www.florion.ru/catalog/buket-na-1-sentyabrya представлены стильные, яркие и креативные композиции, которые дарят преподавателям на 1 сентября. Они зарядят положительными эмоциями, принесут приятные впечатления и станут жестом благодарности. Есть возможность подобрать вариант на любой бюджет: скромный, но не лишенный элегантности или помпезную и большую композицию, которая обязательно произведет эффект. Букеты украшены роскошной зеленью, колосками, которые добавляют оригинальности и стиля.

ArthurWhake –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

gepewFup –

T.me/m1xbet_ru – официальный канал проекта 1XBET. Тут оперативно нужную информацию найдете. 1Xbet удивит вас разнообразием игр. Служба поддержки оперативно реагирует на запросы, заботится о вашем комфорте, а также безопасности. Ищете 1xbet официальный сайт? T.me/m1xbet_ru – здесь рассказываем, почему живое казино нужно выбрать. 1Xbet дает множество возможностей. Букмекер предлагает привлекательные условия для ставок и удерживает пользователей с помощью бонусов и акций. Вывод средств мгновенно осуществляется – это отдельный плюс. Удачи вам в игре мы желаем!

ArthurWhake –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

ArthurWhake –

помощь наркозависимым

hopohiabsob –

Популярный портал помогает повысить финансовую грамотность, самым первым узнать интересующие новости, сведения из мира политики, банков, различных финансовых учреждений. Кроме того, имеются материалы о том, каким бизнесом выгодней заняться. https://sberkooperativ.ru/ – на сайте самые свежие, актуальные данные, которые будут интересны всем, кто интересуется финансами, прибылью. Изучите данные, касающиеся котировок акций. Постоянно появляются любопытные публикации, фото. Отслеживайте их и делитесь с друзьями.

TisujTop –

Посетите сайт https://allforprofi.ru/ это оптово-розничный онлайн-поставщик спецодежды, камуфляжа и средств индивидуальной защиты для широкого круга профессионалов. У нас Вы найдете решения для работников медицинских учреждений, сферы услуг, производственных объектов горнодобывающей и химической промышленности, охранных и режимных предприятий. Только качественная специализированная одежда по выгодным ценам!

ArthurWhake –

помощь наркозависимым

MauriceJence –

dragon money официальный сайт

Pedroskido –

помощь наркозависимым

Richardsnibe –

dragon money зеркало

Jeffreyhip –

сайт драгон мани

Pedroskido –

помощь наркозависимым

TravisUnsex –

dragonmoney

BillyGag –

помощь наркозависимым

BillyGag –

помощь наркозависимым

WilliamgualT –

dragonmoney

Dwightsow –

dragon money

BillyGag –

помощь наркозависимым

BillyGag –

помощь наркозависимым

BillyGag –

помощь наркозависимым

BillyGag –

помощь наркозависимым

BillyGag –

помощь наркозависимым

DexterRon –

помощь наркозависимым

expertCaw –

[url=https://bitvaekstrasensov.su/]Чат с гадалкой онлайн[/url] — это возможность быстро получить ответы на волнующие вопросы. Ты можешь просто задать вопрос и получить мгновенный ответ. Гадание в чате подходит как для быстрых вопросов, так и для глубоких разборов. Ты можешь обратиться к профессиональной гадалке в любое время суток. Сеанс проходит в анонимном формате — никто не узнает о твоем обращении. Гадалка подберет метод в зависимости от твоей ситуации и вопроса. Точные и глубокие ответы — всё благодаря многолетнему опыту гадалок. Чат помогает прояснить любовные отношения, карьерные тупики и внутренние блоки. Ты не один: ежедневно сотни людей обращаются к гадалке онлайн. Один клик — и ты уже общаешься с гадалкой напрямую. Не бойся задать свой вопрос: гадалка не осудит и поможет. Некоторые чаты предоставляют бесплатные сессии или пробные вопросы. Магия перешла в цифровой формат, сохранив свою силу. Гадалка ждет тебя в чате — просто сделай шаг навстречу ответам.

https://bitvaekstrasensov.su/

DexterRon –

помощь наркозависимым

DexterRon –

помощь наркозависимым

Edwardkix –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Jasondon –

https://cvetonya.myqip.ru/?1-0-0-00004660-000-0-0-1751615977

NathanMuh –

https://www.spamweed.com/2023/06/03/the-top-5-benefits-of-having-a-virtual-phone-number-for-your-online-store/

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

yoximEtemy –

Ищете бесплатный сео аудит? Gvozd.org/analyze, здесь вы осуществите проверку ресурса на десятки SЕО параметров и нахождение ошибок, которые, вашему продвижению мешают. Вы ознакомитесь с 80 показателями после анализа сайта. Выбирайте из большой линейки тарифов, в зависимости от ваших целей и задач.

KelvinEnlip –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

Kennethanilk –

помощь наркозависимым

KelvinEnlip –

помощь наркозависимым

piriweAmoma –

«1XBET» считается одной из самых популярных БК, которая предлагает огромное количество вариантов для заработка. Получить дополнительную информацию можно на этом канале, который представляет проект. Отныне канал будет всегда с вами, потому как получить доступ удастся и с телефона. https://t.me/m1xbet_ru – здесь вы найдете не только самую свежую информацию, актуальные новости, но и промокоды. Их выдают при регистрации, на большие праздники. Также имеются и VIP промокоды. Все новое о компании представлено на сайте, где созданы все условия для вас.

Xocerarody –

Auf der Suche nach Replica Rolex, Replica Uhren, Uhren Replica Legal, Replica Uhr Nachnahme? Besuchen Sie die Website – https://www.uhrenshop.to/ – Beste Rolex Replica Uhren Modelle! GROSSTE AUSWAHL. BIS ZU 40 % BILLIGER als die Konkurrenz. DIREKTVERSAND AUS DEUTSCHLAND. HIGHEND ETA UHRENWERKE.

Kennethanilk –

помощь наркозависимым

Georgezef –

помощь наркозависимым

Georgezef –

помощь наркозависимым

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

Georgezef –

помощь наркозависимым

NathanMuh –

https://rationalinsurgent.com/using-a-temp-number-for-telegram/

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

refaciPlalf –

Бизонстрой услуги по аренде спецтехники предоставляет. Предлагаем автокраны, бульдозеры, погрузчики, манипуляторы и другое. Все машины в безупречном состоянии и готовы к немедленному выходу на объект. Думаем, что ваши объекты лучшего заслуживают – выгодных условий и новейшей техники. https://bizonstroy.ru – тут более детальная информация о нас представлена, посмотрите ее уже сегодня. Мы с клиентами нацелены на долгосрочное сотрудничество. Решаем вопросы профессионально и быстро. Обращайтесь и не пожалеете!

Georgezef –

помощь наркозависимым

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

Georgezef –

помощь наркозависимым

NathanMuh –

https://www.digitalconnectmag.com/australian-sms-numbers-revolutionizing/

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

Hicotddiede –

Как выбрать и заказать экскурсию по Казани? Посетите сайт https://to-kazan.ru/tours/ekskursii-kazan и ознакомьтесь с популярными форматами экскурсий, а также их ценами. Все экскурсии можно купить онлайн. На странице указаны цены, расписание и подробные маршруты. Все программы сопровождаются сертифицированными экскурсоводами.

Georgezef –

помощь наркозависимым

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

RobertVor –

https://www.linkedin.com

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

ZodugtDup –

Оригинальные запасные части Thermo Fisher Scientific https://thermo-lab.ru/ и расходные материалы для лабораторного и аналитического оборудования с доставкой в России. Поставка высококачественного лабораторного и аналитического оборудования Thermo Fisher, а также оригинальных запасных частей и расходных материалов от ведущих мировых производителей. Каталог Термо Фишер включает всё необходимое для бесперебойной и эффективной работы вашей лаборатории по низким ценам в России.

WilliamRoums –

dragon money

Eddiegaill –

драгон мани зеркало

Yatuftehenty –

Учебный центр дополнительного профессионального образования НАСТ – https://nastobr.com/ – это возможность пройти дистанционное обучение без отрыва от производства. Мы предлагаем обучение и переподготовку по 2850 учебным направлениям. Узнайте на сайте больше о наших профессиональных услугах и огромном выборе образовательных программ.

Georgezef –

помощь наркозависимым

TyroneShiew –

помощь наркозависимым

ThomasMug –

драгон мани

Georgezef –

помощь наркозависимым

TyroneShiew –

помощь наркозависимым

Georgezef –

помощь наркозависимым

ZomesrdDam –

На сайте https://fakty.org/ изучите свежие новости на самые нашумевшие темы. Они расскажут много нового, чтобы вы были в курсе последних событий. Информация представлена на различную тему, в том числе, экономическую, политическую. Есть данные на тему финансов, рассматриваются вопросы, которые важны всем жителям страны. Вы найдете мнение экспертов о том, что интересует большинство. Все новости поделены на категории для вашего удобства, поэтому вы быстро найдете то, что нужно. Только на этом портале публикуется самая актуальная информация, которая никого не оставит равнодушным.

Claudechado –

помощь наркозависимым

Claudechado –

помощь наркозависимым

Claudechado –

помощь наркозависимым

MichaelAricy –

dragon money официальный сайт

HarveyKache –

dragon money промокод

Chriscresk –

dragonmoney

Claudechado –

помощь наркозависимым

Claudechado –

помощь наркозависимым

Claudechado –

помощь наркозависимым

Luvaflrhith –

Курс Нутрициолог – обучение нутрициологии с дипломом https://nutriciologiya.com/ – ознакомьтесь подробнее на сайте с интересной профессией, которая позволит отлично зарабатывать. Узнайте на сайте кому подойдет курс и из чего состоит работа нутрициолога и программу нашего профессионального курса.

Blakepap –

Внешние котлы

LowellDrorp –

перспектива ломбард

Claudechado –

помощь наркозависимым

Claudechado –

помощь наркозависимым

Blakepap –

Проточный водонагреватель

FrankIdeds –

помощь наркозависимым

LowellDrorp –

rolex оригинал купить

Blakepap –

Дровяная печь для сауны

FrankIdeds –

помощь наркозависимым

MosokBig –

Посетите сайт Digital-агентство полного цикла Bewave https://bewave.ru/ и вы найдете профессиональные услуги по созданию, продвижению и поддержки интернет сайтов и мобильных приложений. Наши кейсы вас впечатлят, от простых задач до самых сложных решений. Ознакомьтесь подробнее на сайте.

FrankIdeds –

помощь наркозависимым

FrankIdeds –

помощь наркозависимым

NathansOf –

https://potofu.me/q1xyorlz

NathansOf –

https://www.band.us/page/99488654/

NathansOf –

https://pxlmo.com/kakabisapaka

Gicudnow –

Посетите сайт https://allcharge.online/ – это быстрый и надёжный сервис обмена криптовалюты, который дает возможность быстрого и безопасного обмена криптовалют, электронных валют и фиатных средств в любых комбинациях. У нас актуальные курсы, а также действует партнерская программа и cистема скидок. У нас Вы можете обменять: Bitcoin, Monero, USDT, Litecoin, Dash, Ripple, Visa/MasterCard, и многие другие монеты и валюты.

Bavogasnib –

Посетите сайт https://artradol.com/ и вы сможете ознакомиться с Артрадол – это препарат для лечения суставов от производителя. На сайте есть цена и инструкция по применению. Ознакомьтесь со всеми преимуществами данного средства, которое является нестероидным противовоспалительным препаратом для лечения суставов. Помогает бороться с основными заболеваниями суставов.

NathansOf –

https://lthhreechahatsea.bandcamp.com/album/berry

NathansOf –

https://say.la/read-blog/122667

NathansOf –

https://rant.li/dauhuadygo/alikante-kupit-ekstazi-mdma-lsd-kokain

NathansOf –

https://hub.docker.com/u/baamigesese

NathansOf –

https://paper.wf/oycteugu/durres-kupit-kokain-mefedron-marikhuanu

lusakbal –

Ищете гражданство паспорт германии евросоюза ес? Expert-immigration.com – это по всему миру квалифицированные юридические услуги. Вам будут предложены консультация по гражданству, ПМЖ и ВНЖ, визам, защита от недобросовестных услуг, помощь в покупке бизнеса. Узнайте подробно на сайте о каждой из услуг, в том числе помощи в оформлении гражданства Евросоюза и других стран или квалицированной помощи в покупке зарубежной недвижимости.

NathansOf –

https://say.la/read-blog/122570

NathansOf –

https://community.wongcw.com/blogs/1126155/%D0%9A%D1%83%D0%BF%D0%B8%D1%82%D1%8C-%D0%9A%D0%BE%D0%BA%D0%B0%D0%B8%D0%BD-%D0%9C%D0%B5%D1%84%D0%B5%D0%B4%D1%80%D0%BE%D0%BD-%D0%9C%D0%B0%D1%80%D0%B8%D1%85%D1%83%D0%B0%D0%BD%D1%83-%D0%9A%D0%BE%D1%80%D1%84%D1%83

NathansOf –

https://eulinkeshek.bandcamp.com/album/animate

NathansOf –

https://hub.docker.com/u/szetocenci

NathansOf –

https://ejatekelixuw.bandcamp.com/album/acute

FelixCat –

https://www.rwaq.org/users/januaryjoannjones1986-20250806155757

FelixCat –

https://potofu.me/7s6mh977

FelixCat –

https://ucgp.jujuy.edu.ar/profile/uhoeydiibou/

DwightJaink –

Шины Rydanz

Peterthowl –

ремонт спальни Алматы

FelixCat –

https://oewarajytyli.bandcamp.com/album/bundle

DwightJaink –

Шины Debica

DwightJaink –

Шины 215/55 R16

FelixCat –

https://say.la/read-blog/122212

Peterthowl –

капитальный ремонт квартир

FelixCat –

https://say.la/read-blog/122540

DwightJaink –

Anvelope 265/50 R20

SinilsJadly –

На сайте https://glavcom.info/ ознакомьтесь со свежими, последними новостями Украины, мира. Все, что произошло только недавно, публикуется на этом сайте. Здесь вы найдете информацию на тему финансов, экономики, политики. Есть и мнение первых лиц государств. Почитайте их высказывания и узнайте, что они думают на счет ситуации, сложившейся в мире. На портале постоянно публикуются новые материалы, которые позволят лучше понять определенные моменты. Все новости составлены экспертами, которые отлично разбираются в перечисленных темах.

expertCaw –

[url=https://bitvaekstrasensov.su/]Чат с гадалкой онлайн[/url] — удобный способ узнать правду о будущем, прошлом или настоящем. Один вопрос — и ты уже на пути к пониманию своей судьбы. Многие пользователи отмечают, что такой формат гадания эффективен и доступен. Онлайн гадалки доступны 24/7 — просто заходи и спрашивай. Полная конфиденциальность и уважение к личной информации гарантированы. Выбирай между таро, рунами, нумерологией и другими техниками. Точные и глубокие ответы — всё благодаря многолетнему опыту гадалок. Гадание — это не просто мистика, а инструмент самоанализа и роста. Ты не один: ежедневно сотни людей обращаются к гадалке онлайн. Ты просто заходишь на сайт и начинаешь чат — проще не бывает. Ты можешь задать вопрос любой сложности — гадалка постарается помочь максимально точно. Даже короткое гадание может дать ценную подсказку на пути к решению. Современные технологии позволяют соединить мудрость и удобство в одном. Гадалка ждет тебя в чате — просто сделай шаг навстречу ответам.

https://bitvaekstrasensov.su/

AlbertOffex –

https://kemono.im/agucudefvegx/kal-iari-kupit-kokain-mefedron-marikhuanu

Peterthowl –

евроремонт квартиры

DwightJaink –

Шины 255/30 R19

DwightJaink –

Anvelope 265/35 R20

AlbertOffex –

https://allmynursejobs.com/author/zerdaahem/

ShawnFic –

https://megancampbellgoldenmeganart052002.bandcamp.com/album/archive

ShawnFic –

https://paper.wf/wdudefvy/kembridzh-kupit-kokain-mefedron-marikhuanu

sharexadE –

[url=https://7sharov.ru]Доставка шариков москва[/url] — это популярный способ порадовать близких в любое время. Вы можете заказать доставка ярких воздушных шаров в любой район Москвы по звонку. Наборы подбираются индивидуально, возможны уникальные дизайны. Будь то день рождения, свадьба или корпоратив — мы сделаем всё красиво. Оформление из воздушных шаров держатся до нескольких дней, доставляются точно в срок. Доступны цифры, фольгированные шары, надписи, фигуры из шаров. Наши курьеры аккуратны и пунктуальны. Сделать заказ легко — достаточно выбрать набор и указать время. Поможем подобрать шары по поводу и бюджету. Мы работаем без выходных и праздников. Гарантируем высокое качество — только сертифицированные изделия. Доступны приятные скидки на большие заказы. Работаем с агентствами, организаторами, корпоративными клиентами. Порадуйте близких — оформите заказ на доставку воздушных шаров.

https://7sharov.ru

Silasvoica –

https://ampibaadpyr.bandcamp.com/album/cheek

sharexadE –

[url=https://7sharov.ru]Доставка воздушных шаров москва[/url] — это удобный способ порадовать близких не выходя из дома. Доступна доставка гелиевых шаров по любому адресу в Москве в мессенджере. Композиции подбираются индивидуально, учитываются все пожелания. Будь то день рождения, свадьба или корпоратив — мы сделаем всё красиво. Шары не сдуваются долго, приезжают вовремя. Цифры, поздравления, оригинальные формы — всё на выбор. Доставка осуществляется профессиональными курьерами. Оформление заказа занимает пару минут. Поддержка всегда на связи — поможем с выбором, подскажем по оформлению. График доставки — 7 дней в неделю, без перерывов. Гарантируем высокое качество — только сертифицированные изделия. Доступны приятные скидки на большие заказы. Открыты к оптовым заказам и постоянному сотрудничеству. Порадуйте близких — оформите заказ на доставку воздушных шаров.

https://7sharov.ru

Justinchody –

https://www.rwaq.org/users/milanapugh-20250804231252

Justinchody –

https://hub.docker.com/u/laurynsilnor

TuyokApale –

Посетите сайт https://artracam.com/ и вы сможете ознакомиться с Артракам – это эффективный препарат для лечения суставов от производителя. На сайте есть цена и инструкция по применению. Ознакомьтесь со всеми преимуществами данного средства – эффективность Артракама при артрите, при остеоартрозе, при остеохондрозе.

Justinchody –

https://community.wongcw.com/blogs/1124236/%D0%9D%D0%BE%D1%80%D0%B2%D0%B5%D0%B3%D0%B8%D1%8F-%D0%BA%D1%83%D0%BF%D0%B8%D1%82%D1%8C-%D0%9C%D0%B0%D1%80%D0%B8%D1%85%D1%83%D0%B0%D0%BD%D1%83-%D0%93%D0%B0%D1%88%D0%B8%D1%88-%D0%91%D0%BE%D1%88%D0%BA%D0%B8

Pefatrddak –

На сайте https://vitamax.shop/ изучите каталог популярной, востребованной продукции «Витамакс». Это – уникальная, популярная линейка ценных и эффективных БАДов, которые улучшают здоровье, дарят прилив энергии, бодрость. Важным моментом является то, что продукция разработана врачом-биохимиком, который потратил на исследования годы. На этом портале представлена исключительно оригинальная продукция, которая заслуживает вашего внимания. При необходимости воспользуйтесь консультацией специалиста, который подберет для вас БАД.

Justinchody –

https://beteiligung.stadtlindau.de/profile/%D0%9A%D1%83%D0%BF%D0%B8%D1%82%D1%8C%20%D0%9A%D0%BE%D0%BA%D0%B0%D0%B8%D0%BD%20%D0%9C%D0%B5%D1%84%D0%B5%D0%B4%D1%80%D0%BE%D0%BD%20%D0%9C%D0%B0%D1%80%D0%B8%D1%85%D1%83%D0%B0%D0%BD%D1%83%20%D0%9F%D0%BE%D1%80%D1%82%D0%B8%D0%BC%D0%B0%D0%BD/

Labejamshout –

На сайте https://expertbp.ru/ получите абсолютно бесплатную консультацию от бюро переводов. Здесь вы сможете заказать любую нужную услугу, в том числе, апостиль, нотариальный перевод, перевод свидетельства о браке. Также доступно и срочное оказание услуги. В компании трудятся только лучшие, квалифицированные, знающие переводчики с большим опытом. Услуга будет оказана в ближайшее время. Есть возможность воспользоваться качественным переводом независимо от сложности. Все услуги оказываются по привлекательной цене.

Justinchody –

https://paper.wf/diugugva/erevan-kupit-ekstazi-mdma-lsd-kokain

MomustCax –

На сайте https://filmix.fans посмотрите фильмы в отличном качестве. Здесь они представлены в огромном многообразии, а потому точно есть, из чего выбрать. Играют любимые актеры, имеются колоритные персонажи, которые обязательно понравятся вам своей креативностью. Все кино находится в эталонном качестве, с безупречным звуком, а потому обязательно произведет эффект. Для того чтобы получить доступ к большому количеству функций, необходимо пройти регистрацию. На это уйдет пара минут. Представлены триллеры, мелодрамы, драмы и многое другое.

Justinchody –

https://say.la/read-blog/122643

Justinchody –

https://git.project-hobbit.eu/ocadqabq

Douglasvax –

https://pxlmo.com/mastansaraya

Douglasvax –

https://hoo.be/qyibegaydp

Vedosved –

Ищете, где заказать надежную кухню на заказ по вашим размерам за адекватные деньги? Посмотрите портфолио кухонной фабрики GLORIA – https://gloriakuhni.ru/ – все проекты выполнены в Санкт-Петербурге и области. На каждую кухню гарантия 36 месяцев, более 800 цветовых решений. Большое разнообразие фурнитуры. Удобный онлайн-калькулятор прямо на сайте и понятное формирование цены. Много отзывов клиентов, видео-обзоры кухни с подробностями и деталями. Для всех клиентов – столешница и стеновая панель в подарок.

Douglasvax –

https://www.passes.com/bunnoazrel

Tagempeclubs –

На сайте https://rusvertolet.ru/ воспользуйтесь возможностью заказать незабываемый, яркий полет на вертолете. Вы гарантированно получите много положительных впечатлений, удивительных эмоций. Важной особенностью компании является то, что полет состоится по приятной стоимости. Вертолетная площадка расположена в городе, а потому просто добраться. Компания работает без выходных, потому получится забронировать полет в любое время. Составить мнение о работе помогут реальные отзывы. Прямо сейчас ознакомьтесь с видами полетов и их расписанием.

Douglasvax –

https://www.rwaq.org/users/camuabsant-20250806005150

Douglasvax –

https://kemono.im/xodegmyihieb/marmaris-kupit-gashish-boshki-marikhuanu

Douglasvax –

https://ucgp.jujuy.edu.ar/profile/odbiyyge/

Douglasvax –

https://www.rwaq.org/users/browneyes28house-20250806215401

Kavownab –

Ищете рейтинг лучших сервисов виртуальных номеров? Посетите страницу https://blog.virtualnyy-nomer.ru/top-15-servisov-virtualnyh-nomerov-dlya-priema-sms и вы найдете ТОП-15 сервисов виртуальных номеров для приема СМС со всеми их преимуществами и недостатками, а также личный опыт использования.

Douglasvax –

https://kemono.im/yaihyfuabyyb/shri-lanka-kupit-ekstazi-mdma-lsd-kokain

vahoyFlors –

Ищете медицинское оборудование с завода? Agsvv.ru/catalog/obluchateli_dlya_lecheniya/obluchatel_dlya_lecheniya_psoriaza_ultramig_302/ и вы отыщите для покупки от производителя Облучатель ультрафиолетовый Ультрамиг-302М, также сможете с отзывами, описанием, преимуществами и его характеристиками ознакомиться. Узнайте для кого подходит и какие заболевания лечит. Купить от псориаза и иных заболеваний облучатель, а также другую продукцию, вы сможете от производителя – компании Хронос напрямую.

Douglasvax –

https://community.wongcw.com/blogs/1125107/%D0%9A%D1%83%D0%BF%D0%B8%D1%82%D1%8C-%D0%AD%D0%BA%D1%81%D1%82%D0%B0%D0%B7%D0%B8-%D0%9C%D0%94%D0%9C%D0%90-%D0%9A%D0%BE%D0%BA%D0%B0%D0%B8%D0%BD-%D0%A4%D1%83%D0%BD%D1%88%D0%B0%D0%BB

Douglasvax –

https://say.la/read-blog/122284

Douglasvax –

https://allmynursejobs.com/author/bigboyluxdrik7/

Douglasvax –

https://www.brownbook.net/business/54134725/купить-кокаин-баден-баден/

Douglasvax –

https://imageevent.com/uaqgorshkova/utvpi

Douglasvax –

https://pxlmo.com/Gonzalez_barbaras19710

Douglasvax –

https://bio.site/ugihafeb

RideyllOppop –

Интернет магазин электроники «IZICLICK.RU» отменные товары предоставляет. У нас можете купить: мониторы, принтеры, моноблоки, сканеры и МФУ, ноутбуки, телевизоры и другое. Выгодные предложения и приемлемые цены мы гарантируем. Стремимся сделать ваши покупки максимально комфортными. https://iziclick.ru – портал, где вы отыщите подробные описания товара, отзывы, фотографии и характеристики. Предоставим вам профессиональную консультацию и поможем сделать оптимальный выбор. Доставим по Москве и области ваш заказ.

Douglasvax –

https://rant.li/ydlxagibhag/vengriia-kupit-ekstazi-mdma-lsd-kokain

GeorgeEthig –

https://allmynursejobs.com/author/pospehzobaer/

GeorgeEthig –

https://imageevent.com/kwiziahonen/mdivw

Ligocrmit –

На сайте https://iziclick.ru/ в большом ассортименте представлены телевизоры, аксессуары, а также компьютерная техника, приставки, мелкая бытовая техника. Все товары от лучших, проверенных марок, потому отличаются долгим сроком эксплуатации, надежностью, практичностью, простотой в применении. Вся техника поставляется напрямую со склада производителя. Продукция является оригинальной, сертифицированной. Реализуется по привлекательным расценкам, зачастую устраиваются распродажи для вашей большей выгоды.

GeorgeEthig –

https://beteiligung.stadtlindau.de/profile/%D0%9A%D1%83%D0%BF%D0%B8%D1%82%D1%8C%20%D0%91%D0%BE%D1%88%D0%BA%D0%B8%20%D0%9C%D0%B0%D1%80%D0%B8%D1%85%D1%83%D0%B0%D0%BD%D1%83%20%D0%93%D0%B0%D1%88%D0%B8%D1%88%20%D0%A0%D0%B8%D1%88%D0%BE%D0%BD-%D0%BB%D0%B5-%D0%A6%D0%B8%D0%BE%D0%BD/

DustinFuh –

https://potofu.me/6d4mw1wy

DustinFuh –

https://git.project-hobbit.eu/rpogydecy

CharlieJak –

https://allmynursejobs.com/author/mrkatdarkdreamer2/

sekimiGaict –

Бывают такие ситуации, когда требуется помощь хакеров, которые быстро, эффективно справятся с самой сложной задачей. Хакеры легко вскроют почту, добудут пароли, обеспечат защиту. Для решения задачи применяются только проверенные, эффективные способы. Любой хакер отличается большим опытом. https://hackerlive.biz – сайт, на котором находятся только лучшие в своей области профессионалы. За оказание услуги плата небольшая. Но при этом оказывают услуги на высоком уровне. Прямо сейчас свяжитесь со специалистом, который отвечает вашим требованиям.

RichardBrofe –

https://bio.site/afooaydibc

RichardBrofe –

https://pxlmo.com/pintamiataug

RichardBrofe –

https://hoo.be/xvigpege

KepusszeP –

На сайте https://cvetochnik-doma.ru/ вы найдете полезную информацию, которая касается комнатных растений, ухода за ними. На портале представлена информация о декоративно-лиственных растениях, суккулентах. Имеются материалы о цветущих растениях, папоротниках, пальмах, луковичных, экзотических, вьющихся растениях, орхидеях. Для того чтобы найти определенную информацию, воспользуйтесь специальным поиском, который подберет статью на основе запроса. Для большей наглядности статьи сопровождаются красочными фотографиями.

WifijySuimi –

Посетите сайт https://ambenium.ru/ и вы сможете ознакомиться с Амбениум – единственный нестероидный противовоспалительный препарат зарегистрированный в России с усиленным обезболивающим эффектом – раствор для внутримышечного введения фенилбутазон и лидокаин. На сайте есть цена и инструкция по применению. Ознакомьтесь со всеми преимуществами данного средства.

Proballooning –

This content 📝 perfectly explains 💡 concepts that 🎯 I struggled 🤔 to understand before now

RichardBrofe –

https://www.brownbook.net/business/54138879/купить-кокаин-марихуану-мефедрон-плайя-дель-кармен/

RichardBrofe –

https://community.wongcw.com/blogs/1126772/%D0%9A%D1%83%D0%BF%D0%B8%D1%82%D1%8C-%D0%AD%D0%BA%D1%81%D1%82%D0%B0%D0%B7%D0%B8-%D0%9C%D0%94%D0%9C%D0%90-%D0%9A%D0%BE%D0%BA%D0%B0%D0%B8%D0%BD-%D0%94%D0%B0%D0%BD%D0%B0%D0%BD%D0%B3

LogivlFrasy –

На сайте https://kino.tartugi.name/kolektcii/garri-potter-kolekciya посмотрите яркий, динамичный и интересный фильм «Гарри Поттер», который представлен здесь в отменном качестве. Картинка находится в высоком разрешении, а звук многоголосый, объемный, поэтому просмотр принесет исключительно приятные, положительные эмоции. Фильм подходит для просмотра как взрослыми, так и детьми. Просматривать получится на любом устройстве, в том числе, мобильном телефоне, ПК, планшете. Вы получите от этого радость и удовольствие.

RichardBrofe –

https://hoo.be/ugpnuhahjyci

Danielpaf –

https://hoo.be/uugufuba

Danielpaf –

https://allmynursejobs.com/author/maskargysel/

Robertscash –

https://hub.docker.com/u/tejribrichie

zegojsat –

РусВертолет – компания, которая занимает лидирующие позиции среди конкурентов по качеству услуг и доступной ценовой политики. Работаем 7 дней в неделю. Наш основной приоритет – ваша безопасность. Вертолеты в отменном состоянии, оперативно полет заказать вы на ресурсе можете. Обеспечим вам море положительных и ярких эмоций! Ищете экскурсия на вертолете нижний новгород стоимость? Rusvertolet.ru – тут есть видео и фото полетов, а также отзывы радостных клиентов. Вы узнаете, где мы находимся и как добраться. Подготовили ответы на популярные вопросы о полетах на вертолете. Всегда вам рады!

Robertscash –

https://kemono.im/hxacafyhah/kireniia-kupit-ekstazi-mdma-lsd-kokain

Robertbit –

https://pxlmo.com/johllkuziogc

Robertscash –

https://paper.wf/yedyceda/vatikan-kupit-ekstazi-mdma-lsd-kokain

LexivtEmaix –

На сайте https://selftaxi.ru/ вы сможете задать вопрос менеджеру для того, чтобы узнать всю нужную информацию о заказе минивэнов, микроавтобусов. В парке компании только исправная, надежная, проверенная техника, которая работает отлаженно и никогда не подводит. Рассчитайте стоимость поездки прямо сейчас, чтобы продумать бюджет. Вся техника отличается повышенной вместимостью, удобством. Всегда в наличии несколько сотен автомобилей повышенного комфорта. Прямо сейчас ознакомьтесь с тарифами, которые всегда остаются выгодными.

Eugenevib –

https://vashdomufa.ru

Michaelpudge –

https://itravel-vl.ru

Eugenevib –

https://rostokino-dez.online

Eugenevib –

https://somovarmor.ru

Michaelpudge –

https://citywolf.online

Eugenevib –

https://art-vis.ru

Eugenevib –

https://cdo-aw.ru

Michaelpudge –

https://pro-store-apple.ru

JamesOxymn –

Commencez à trader en toute confiance avec pocket option français et profitez d’une plateforme intuitive et performante

Eugenevib –

https://jycs.ru

Eugenevib –

https://shatura-stupino.ru

Michaelpudge –

https://vlgprestol.online

Eugenevib –

https://respublika1.online

DonaldTarge –

Проверенные способы заработка в интернете

Jeffreytah –

https://lenovo-russia.ru

LarryMed –

https://citywolf.online

Jeffreytah –

https://tavatuy-rzd.ru

Jeffreytah –

https://vintage-nsk.online

LarryMed –

https://glavkupol.ru

Jeffreytah –

https://itravel-vl.ru

Jeffreytah –

https://glavkupol.ru

LarryMed –

https://crocus-opt.ru

Jeffreytah –

https://ooo-mitsar.online

Jeffreytah –

https://montera-kurort.ru

LarryMed –

https://vlgprestol.online

Henryjek –

Lucknow Game: Immerse yourself in the cultural heritage of Lucknow, solving puzzles and exploring iconic landmarks to uncover hidden treasures: official Lucknow game portal

Jeffreytah –

https://respublika1.online

Jeffreytah –

https://hockeyempire.ru

LarryMed –

https://rostokino-dez.online

Williamsor –

השולחן בעקבים, שם היא מצאה את עצמה מיד בזרועותיו של גבר חתיך שרירי וערום. ויקה לא רצתה להביט כמה קוקטיילים, כשההידוק שלה התמוסס לאלכוהול. והוא החליט: הגיע הזמן לפעול. מקס בחר את הרגע בצורה על נערת ליווי מחיר ומה שביניהם

Jeffreytah –

https://art-vis.ru

Jeffreytah –

https://art-of-pilates.ru

LarryMed –

https://citywolf.online

Jeffreytah –

https://rbx-shop.ru

LarryMed –

https://art-of-pilates.ru

mozuxaFib –

Rz-Work – биржа для опытных профессионалов и новичков, которые к ответственной работе готовы. Популярность у фриланс-сервиса высокая. Преимущества, которые пользователи выделили: оперативное реагирование службы поддержки, простота регистрации, гарантия безопасности сделок. https://rz-work.ru – здесь представлена более подробная информация. Rz-Work является платформой, способствующей эффективному взаимодействию исполнителей и заказчиков. Она понятным интерфейсом отличается. Площадка многопрофильная, она много категорий охватывает.

Jeffreytah –

https://pointgtoys.ru

LarryMed –

https://shatura-stupino.ru

zumegErync –

CyberGarden – лучшее место для покупки цифрового оборудования. Интернет-магазин предоставляет богатый выбор высококачественной продукции с хорошим сервисом. Вас порадуют доступные цены. https://cyber-garden.com – тут можете подробнее с условиями доставки и оплаты ознакомиться. CyberGarden предоставляет легкий процесс заказа и удобный интерфейс, превращая в удовольствие онлайн-покупки. Для нас бесценно доверие клиентов, поэтому мы к работе с огромной ответственностью подходим. Грамотную консультацию мы вам гарантируем.

PROBallooning –

Your work continues to make a 🌻 🚀 💕 real difference in communities worldwide

Jeffreytah –

https://vashdomufa.ru

LarryMed –

https://rbx-shop.ru

Jeffreytah –

https://crystal-tv.ru

LarryMed –

https://respublika1.online

Jeffreytah –

https://printbarglobal.ru

LarryMed –

https://rostokino-dez.online

Jeffreytah –

https://cdo-aw.ru

LarryMed –

https://pro-store-apple.ru

Jeffreytah –

https://kanscity.online

PeterNiple –

camera rose khutor

JugaxtPed –

На сайте https://vc.ru/crypto/2131965-fishing-skam-feikovye-obmenniki-polnyi-gaid-po-zashite-ot-kripto-moshennikov изучите информацию, которая касается фишинга, спама, фейковых обменников. На этом портале вы ознакомитесь с полным гайдом, который поможет вас защитить от мошеннических действий, связанных с криптовалютой. Перед вами экспертная статья, которая раскроет множество секретов, вы получите огромное количество ценных рекомендаций, которые будут полезны всем, кто имеет дело с криптовалютой.

Jeffreytah –

https://integral-msk.ru

BrandonFep –

Топливные карты для юр лиц

LarryMed –

https://ooo-mitsar.online

Jeffreytah –

https://pro-store-apple.ru

Kennethfen –

https://telegra.ph/Kak-pravilno-vybrat-zapchasti-dlya-separatorov-08-02

RobertEtecy –

Москва Новомосковский

PeterNiple –

webcam saint petersburg

LeroyNow –

http://www.birulevo.su/component/option,com_smf/Itemid,34/topic,26581.0/

Peterpathy –

https://rostokino-dez.online

RobertEtecy –

Махачкала

RobertEtecy –

Слободской

guvonJeami –

T.me/m1xbet_ru – канал проекта 1Xbet официальный. Здесь исключительно важная информация представлена. Большинство считают 1Xbet лучшим из букмекеров. Платформа дарит азарт, яркие эмоции и имеет понятную навигацию. Специалисты службы поддержки при необходимости всегда готовы помочь. https://t.me/m1xbet_ru – тут отзывы игроков о 1xBET представлены. Платформа старается удерживать пользователей с помощью актуальных акций. Вывод средств проходит без проблем. Все четко и быстро работает. Желаем вам ставок удачных!

Peterpathy –

https://abz-istok.online

RobertEtecy –

Куса

RobertEtecy –

Червиния

Peterpathy –

https://crovlyagrad.online

RobertEtecy –

Добрна

Kennethfen –

https://telegra.ph/Zapchasti-dlya-gomogenizatorov-sovety-po-diagnostike-08-02

Vucepargus –

На сайте https://papercloud.ru/ вы отыщете материалы на самые разные темы, которые касаются финансов, бизнеса, креативных идей. Ознакомьтесь с самыми актуальными трендами, тенденциями из сферы аналитики и многим другим. Только на этом сайте вы найдете все, что нужно, чтобы правильно вести процветающий бизнес. Ознакомьтесь с выбором редакции, пользователей, чтобы быть осведомленным в многочисленных вопросах. Представлена информация, которая касается капитализации рынка криптовалюты. Опубликованы новые данные на тему бизнеса.

RobertEtecy –

Москва Капотня

MolufamCex –

На сайте https://selftaxi.ru/miniven6 закажите такси минивэн, которое прибудет с водителем. Автобус рассчитан на 6 мест, чтобы устроить приятную поездку как по Москве, так и области. Это комфортабельный, удобный для передвижения автомобиль, на котором вы обязательно доедете до нужного места. Перед рейсом он обязательно проверяется, проходит технический осмотр, а в салоне всегда чисто, ухоженно. А если вам необходимо уточнить определенную информацию, то укажите свои данные, чтобы обязательно перезвонил менеджер и ответил на все вопросы.

Peterpathy –

https://crovlyagrad.online

RobertEtecy –

Хакасия

RobertEtecy –

Святогорск

RobertEtecy –

Уганда

Peterpathy –

https://oknapsk.online

Davidpag –

блог по раскрутке

Kennethfen –

https://telegra.ph/Tipy-oborudovaniya-dlya-molochnoj-promyshlennosti-08-02

RobertEtecy –

Елизово

Peterpathy –

https://kanscity.online

RobertEtecy –

Чэнду

RobertEtecy –

Бекасово

Peterpathy –

https://alar8.online

RobertEtecy –

Охрид

Rafaeldeare –

Москва Беговой

Jeffreyhat –

https://vlgprestol.online

Rafaeldeare –

Гафса

Rafaeldeare –

Томилино

Pukofanype –

На сайте https://eliseevskiydom.ru/ изучите номера, один из которых вы сможете забронировать в любое, наиболее комфортное время. Это – возможность устроить уютный, комфортный и незабываемый отдых у Черного моря. Этот дом находится в нескольких минутах ходьбы от пляжа. Здесь вас ожидает бесплатный интернет, просторные и вместительные номера, приятная зеленая терраса, сад. Для того чтобы быстрее принять решение о бронировании, изучите фотогалерею. Имеются номера как для семейных, так и тех, кто прибыл на отдых один.

Jeffreyhat –

https://abz-istok.online

Rafaeldeare –

Шладминг

Patrickgag –

Москва Орехово-Борисово Северное

StephenRep –

יאהב את הגברת שלו יותר אם הוא לא הראשון. הוא יעריץ אותה, ו “ייצא מהעור” כדי שתוכל לשכוח את הגברים התחת הצמוד של כלתו, נראה שאבא שלי התחדש וזרק יותר מתריסר שנים. הוא עבד כל כך קשה על אישה שמתאימה you could look here

JasonKaf –

https://citywolf.online

Patrickgag –

Маргилан

Patrickgag –

Нарва

JasonKaf –

https://abz-istok.online

Patrickgag –

Кочкор-Ата

DavidEncuh –

Бибирево

WukabnbeW –

На сайте https://seobomba.ru/ ознакомьтесь с информацией, которая касается продвижения ресурса вечными ссылками. Эта компания предлагает воспользоваться услугой, которая с каждым годом набирает популярность. Получится продвинуть сайты в Google и Яндекс. Эту компанию выбирают по причине того, что здесь используются уникальные, продвинутые методы, которые приводят к положительным результатам. Отсутствуют даже незначительные риски, потому как в работе используются только «белые» методы. Тарифы подойдут для любого бюджета.

Timothycom –

https://rukavkaz.ru/pitanie/44631-cardirin-moj-opyt-lecheniya-gipertonii-s-naturalnymi-kaplyami

DavidEncuh –

Вилла Каналес

Arthursoarm –

https://citywolf.online

DavidEncuh –

Вудлендс

DavidEncuh –

Протвино

Arthursoarm –

https://vlgprestol.online

DavidEncuh –

Тинь

Timothycom –

https://med-pro-ves.ru/zdorove/cardirin-naturalnye-kapli-dlya-kontrolya-arterialnogo-davleniya-i-podderzhki-serdtsa

DavidEncuh –

Брешиа

Arthursoarm –

https://alar8.online

Jamesdrarm –

ZType Game: An adrenaline-pumping typing shooter where fast fingers destroy words incoming from space-speed and accuracy win the game: best alternatives to ZType

Michaeldup –

Нововоронеж

Jasperarrok –

https://respublika1.online

Michaeldup –

Москва Новогиреево

Antoniajex –

Приморский край

AnthonyHut –

https://rostokino-dez.online

Antoniajex –

Абаша

Antoniajex –

Москва Дорогомилово

Antoniajex –

Вуокатти

AnthonyHut –

https://e3-studio.online

Mociztguelp –

Посетите сайт https://cs2case.io/ и вы сможете найти кейсы КС (КС2) в огромном разнообразии, в том числе и бесплатные! Самый большой выбор кейсов кс го у нас на сайте. Посмотрите – вы обязательно найдете для себя шикарные варианты, а выдача осуществляется моментально к себе в Steam.

Antoniajex –

Писсури

Antoniajex –

Лезье

AnthonyHut –

https://vintage-nsk.online

Curtismug –

שולה מוקשים בשדה מוקשים. בארוחת הערב, אחרי כוס יין, הוא יכול היה לזרוק משהו כמו, ” האם תרצה לנסות לחזיית בגד הים, ירכיה התרחבו מעט יותר ומותניה עדיין היו צרות באותה מידה, מה שהלך לה מאוד. לא her explanation

Antoniajex –

Нисеко

Antoniajex –

Менорка

Derickwacle –

https://oknapsk.online

MorrisZigma –

Ляховичи

Donaldrably –

https://pxlmo.com/nthagasorcia

Davidpag –

https://s-sd.ru/blog_soc/

Donaldrably –

https://ucgp.jujuy.edu.ar/profile/yduecohu/

TitusRaita –

https://www.band.us/page/99569977/

Shermanrit –

https://wanderlog.com/view/eqvcramqsl/

Shermanrit –

https://allmynursejobs.com/author/yvetttl0l/

TitusRaita –

https://pxlmo.com/burkscourtney10

Shermanrit –

https://pxlmo.com/gentleEarlinebrightEarlineme13

Timothycom –

https://womanfan.ru/cardirin-tsena-i-effektivnost-ekspertnoe-mnenie-o-naturalnyh-kaplyah-ot-gipertonii/

Shermanrit –

https://muckrack.com/person-27432333

TitusRaita –

https://rant.li/82x1o2zzps

Shermanrit –

https://aledozekre.bandcamp.com/album/anymore

Shermanrit –

https://hub.docker.com/u/xniceLeninhalife

TitusRaita –

https://muckrack.com/person-27432167

Shermanrit –

https://www.montessorijobsuk.co.uk/author/jxafwefdje/

Shermanrit –

https://potofu.me/5zzxp5f7

TitusRaita –

https://potofu.me/i9h9o69t

Shermanrit –

https://www.rwaq.org/users/dhdelrays-20250808150233

Shermanrit –

https://community.wongcw.com/blogs/1128716/%D0%98%D0%B1%D0%B8%D1%86%D0%B0-%D0%90%D0%BC%D1%84%D0%B5%D1%82%D0%B0%D0%BC%D0%B8%D0%BD-%D0%9A%D0%BE%D0%BA%D0%B0%D0%B8%D0%BD-%D0%AD%D0%BA%D1%81%D1%82%D0%B0%D0%B7%D0%B8

Shermanrit –

https://www.metooo.io/u/689751e650f8135b8ecb6308

TitusRaita –

https://odysee.com/@Haarmanbad

Shermanrit –

https://community.wongcw.com/blogs/1128552/%D0%9A%D0%BE%D1%81%D1%82%D0%B0-%D0%91%D1%80%D0%B0%D0%B2%D0%B0-%D0%9C%D0%B0%D1%80%D0%B8%D1%85%D1%83%D0%B0%D0%BD%D0%B0-%D0%93%D0%B0%D1%88%D0%B8%D1%88-%D0%9A%D0%B0%D0%BD%D0%B0%D0%B1%D0%B8%D1%81

Shermanrit –

https://paper.wf/ybsoodoci/vanadzor-kupit-ekstazi-mdma-lsd-kokain