The factors effect the price of White fused alumina/White corundom/White alumina oxide/WFA

The price of White fused alumina/White corundom/White alumina oxide/WFA is mainly affected by the following factors:

Raw material cost

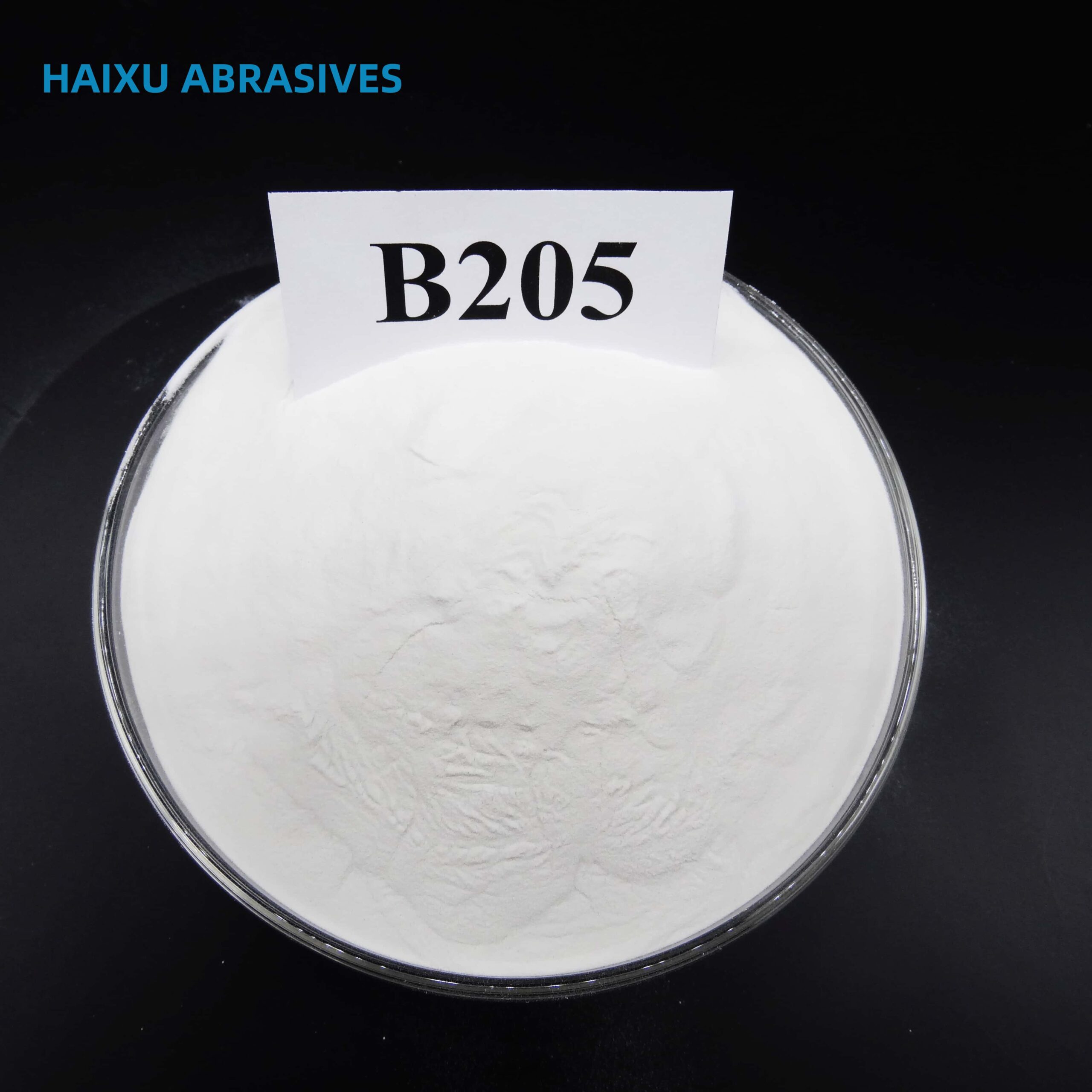

The main raw material of White fused alumina/White corundom/White alumina oxide/WFA is industrial alumina powder. The increase in the price of alumina directly leads to an increase in the production cost of white corundum. In addition, the tight supply of alumina also keeps its price high, further pushing up the price of white corundum.

Production cost

During the production process of white corundum, electricity costs, transportation costs, and labor costs will affect its price. For example, the increase in electricity costs and the import cost of raw materials will increase the production cost, thereby affecting the price of the final product.

Quality

The quality of white corundum is also an important factor in determining its price. High-quality white corundum usually has higher purity and crystallinity, and these characteristics make it more expensive.

Market demand

White corundum has a wide range of applications in industry, such as glass, ceramic processing, and mechanical parts manufacturing. Changes in market demand will directly affect the price of white corundum. For example, when market demand increases, the price of white corundum may rise.

Production process

Different production processes will affect the performance and cost of white corundum. For example, white corundum produced by the fusion method has higher purity and crystallinity and is suitable for high-end applications, while white corundum produced by the sintering method is suitable for mid- and low-end applications.

Regional differences

The price of white corundum in different regions may vary, which is mainly due to factors such as supply and demand between regions, logistics costs, and market competition. In summary, the price of white corundum is affected by many factors such as raw material cost, production cost, quality, market demand, production process, and regional differences.