Physical and chemical properties of aluminum hydroxide

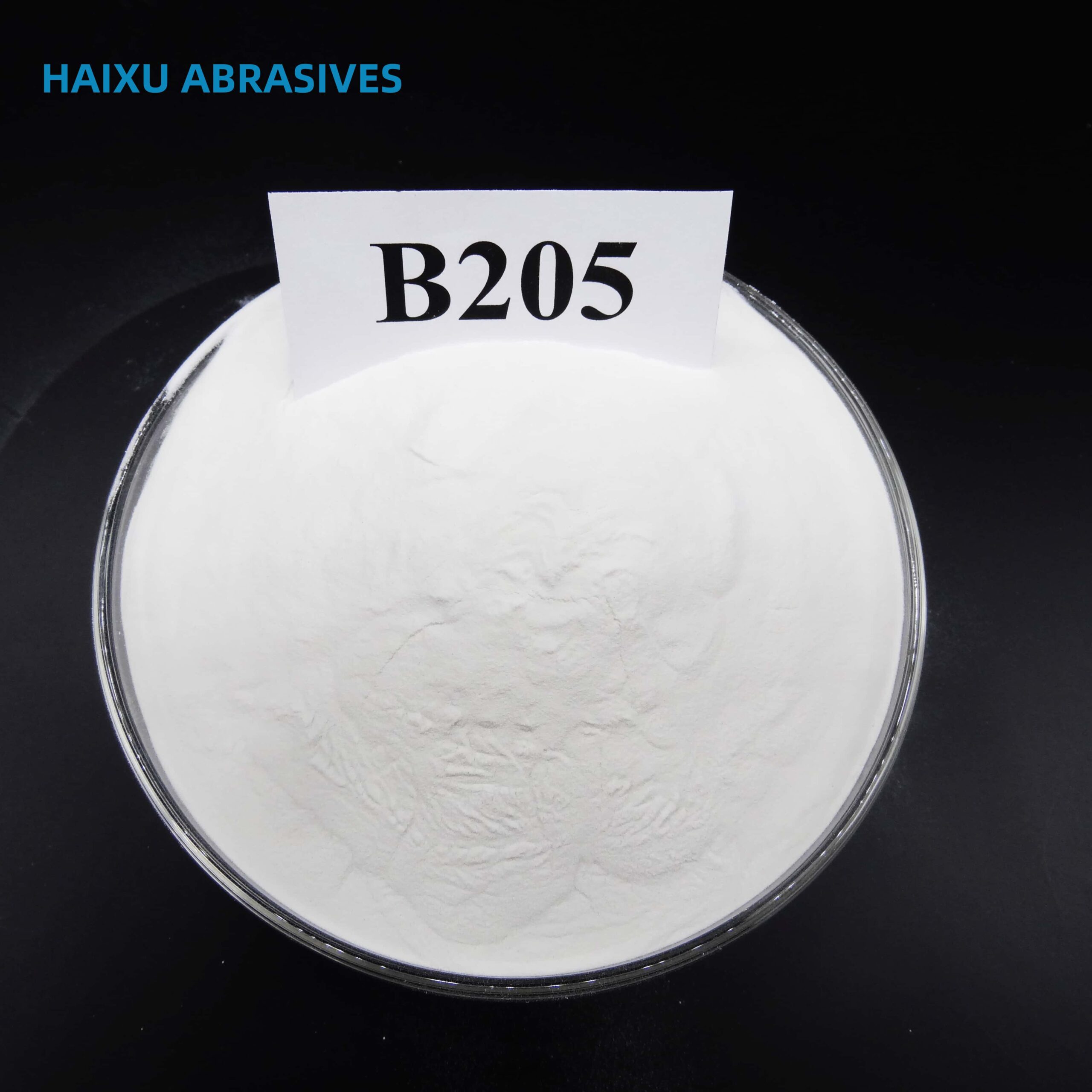

Aluminum hydroxide, also known as aluminic acid, is an inorganic compound with the chemical formula Al(OH)3. It is a white crystal with the properties of hygroscopicity and solubility in alkaline media. In addition, aluminum hydroxide has a large specific surface area and is easy to combine with fillers such as epoxy resin, so it is widely used in filler additives.

The role of aluminum hydroxide in epoxy fillers

1. Increase the hardness and wear resistance of fillers

Due to the high hardness of aluminum hydroxide, adding it to epoxy fillers can improve its physical properties and wear resistance, making the fillers have better durability and mechanical properties.

2. Improve the weather resistance and fire resistance of fillers

Epoxy fillers are easily affected by ultraviolet rays, high temperature, humidity and other factors during long-term use, which can cause the entire filler layer to fall off and be damaged. Adding an appropriate amount of aluminum hydroxide can improve the weather resistance of the filler and effectively reduce the decrease in the hardness and embrittlement of the filler. In addition, aluminum hydroxide has good thermal stability and can also improve the fire resistance of the filler to a certain extent, ensuring safe and stable use.

3. Adjust the density and color of the filler

Since aluminum hydroxide has a lower density, it can play a role in adjusting the density in the filler to ensure the uniformity and aesthetics of the filler. In addition, the white color of aluminum hydroxide can also play a lubricating role in the filler, making the filler easy to lubricate and process.

In short, aluminum hydroxide, as an additive in epoxy fillers, can improve the hardness, wear resistance, weather resistance, fire resistance, and adjust the density and color of the filler. It is a commonly used epoxy filler additive.