Zirconium oxide beads as a high-performance grinding medium are widely used in ceramics, coatings, chemicals, medicine and other fields. Its unique physical and chemical properties make zirconia beads perform well in the grinding and dispersion process. The production process of zirconia beads, especially its molding method, has a crucial impact on the performance of the product.

The following are three common methods for zirconia bead production.

- Pressing molding method

The pressing molding method, that is, dry pressing of powder, is a traditional method for zirconia bead production. This method is easy to operate and suitable for the production of large-diameter zirconium beads. During the pressing process, zirconia beads of different specifications and shapes can be produced by adjusting the shape and size of the mold. However, the pressing molding method also has certain limitations. Since the pressure control during the pressing process is crucial, excessive pressure will cause cracks inside the zirconium beads, affecting their strength; while too little pressure will not make the powder fully dense, resulting in low sphericity of the zirconium beads. Therefore, in actual operation, the pressing pressure needs to be strictly controlled to ensure the quality and performance of the zirconium beads.

- Rolling ball method

The rolling ball method is one of the main ways to mass produce zirconium oxide beads in China. This method gradually gathers the powder into a spherical shape by rolling, with low preparation cost and fast production speed. The advantage of the rolling ball method is that zirconium beads can be produced in large quantities to meet market demand. However, since the zirconium beads are enlarged layer by layer during the rolling process, their density will be slightly lower than other production methods. This leads to higher wear and tear of the rolled zirconium beads during the grinding process and a relatively short service life. In order to improve the performance of the rolled zirconium beads, heat treatment and other methods can be used to improve their density and strength.

- Titration method

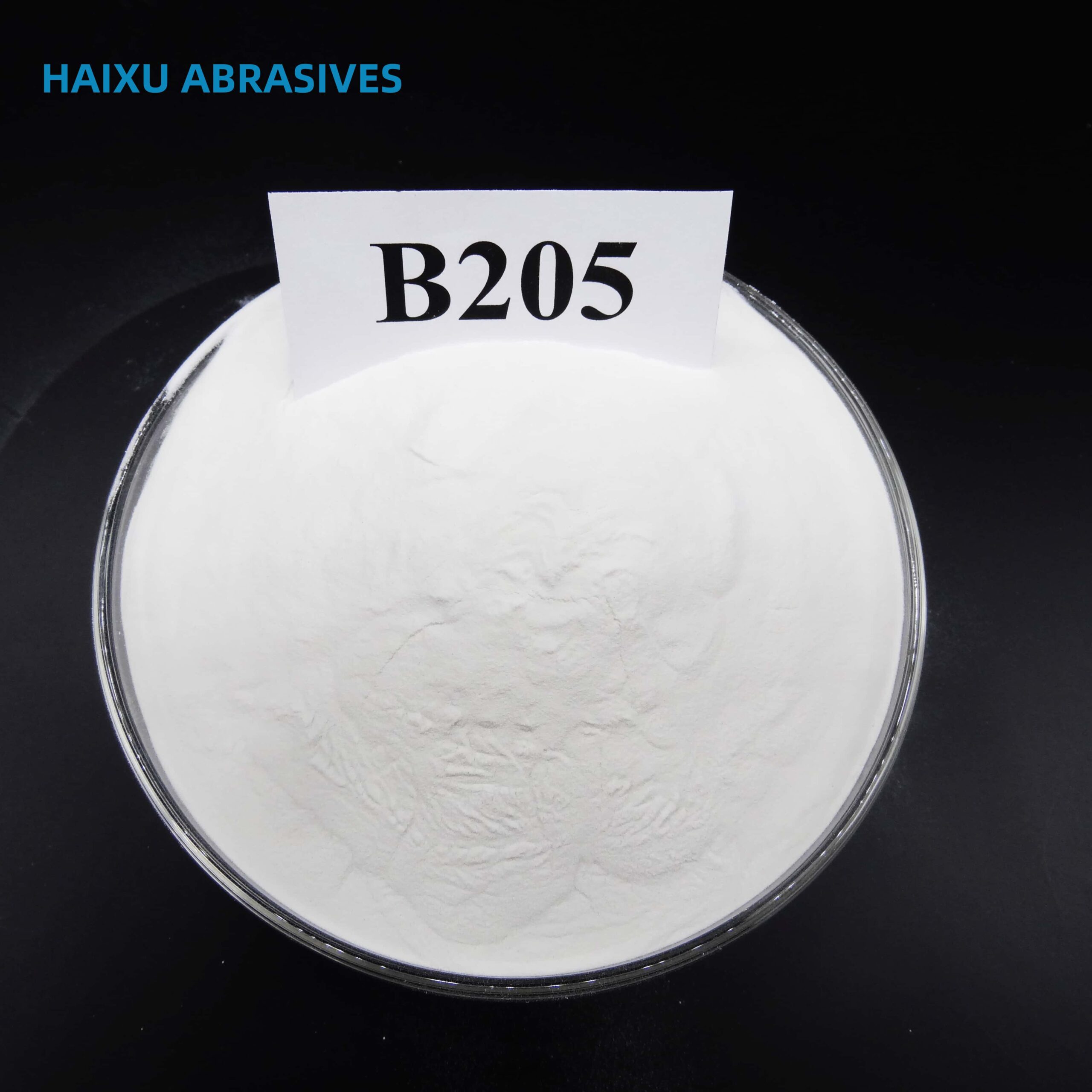

The titration method is a more advanced method for producing zirconium oxide beads. During the production process, the surface tension of the suspended zirconium bead droplets in the dielectric is controlled to make them naturally form a sphere. The zirconium beads produced by this method have high sphericity, smooth surface and excellent grinding performance. However, the production speed of the titration method is relatively slow and the cost is high. Therefore, in practical applications, it is necessary to make a comprehensive consideration based on product demand and production cost.